ADTO News

-

Do You Know the Components of Table Formwork System?

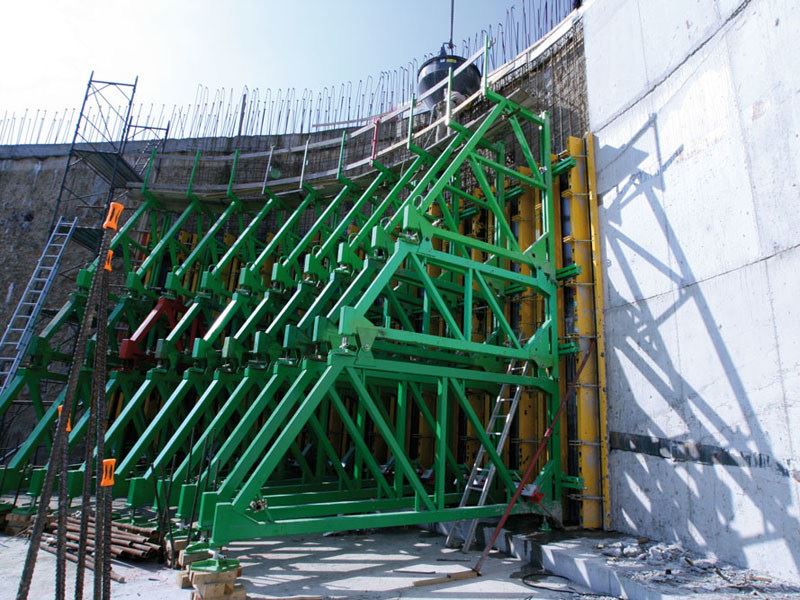

Table Formwork System is a kind of shuttering specializing in floor concreting and it is widely used in high building and skyscraper, multi-layer industrial factory building, substructure, etc. Table formwork system has a simple structure, it is easy to assemble and disassemble and can be reusable.

2019-12-06 -

Different Types of Table Formwork System

There are three types of table formwork system as follows.

2019-12-04 -

Do You Know the Advantages of Table Formwork System?

Do you know the advantages of the table formwork system? Today, we listed the advantages the table formwork systems have for your consideration.

2019-12-03 -

Advantages of Stainless Steel Pipe Fitting

In the future, China’s stainless steel pipe fitting market will have rapid growth and development in many fields. This is the current development trend. There is no doubt that as an enterprise, how to deal with the development, while doing a good job in quality management of stainless steel materials, forming process, wall thickness change and solution (heat treatment) and other quality management, it is also necessary to do a good job in the implementation and guidance of product quality and technical specifications, so that more users It is a systematic project to understand the function, use, and maintenance of the products, accelerate the popularization of stainless steel water supply pipe fittings and increase the market share, and promote the application of stainless steel pipe fittings in various fields. It also needs the cooperation and efforts of all links and all aspects.

2019-11-29 -

Factors Affecting The Performance and Service Life of Stainless Steel Pipe Fittings

Compared to other kinds of steel pipe fitting, Stainless steel pipe fitting has a long service life. The service life of stainless steel pipe fitting can reach 100 years, at least 70 years, as same as the life of buildings. The most outstanding advantage of stainless steel pipe fittings is corrosion resistance. If the stainless steel pipe fittings can be used and maintained correctly in the use process, the service life can be effectively extended.

2019-11-29 -

Conclusion on the Application of Concrete Formwork Technology in Construction

Here we come to the end of this passage. And we have concluded our points as follows. The rapid development of the construction industry has made construction technology and the quality of engineering projects become the most concerned content of a society. In the process of construction, the technical cost of the concrete formwork is low. While concrete formwork technology plays an important role in improving the robustness and stability of buildings. However, in the process of applying concrete formwork technology, there are also some skills and methods.

2019-11-27 -

Demolition of Cast-in-place Frame Structure and Column Formwork

The removal procedure of cast-in-place frame structure and column formwork

2019-11-27 -

General Requirements For Formwork Removal

Here we listed the detailed requirements for the removal of formwork as follows.

2019-11-26 -

What’s the Time Should the Formwork Be Removed During Construction?

What’s the time should the formwork be removed during construction? We have written this passage to help you better understand the hardening of the concrete and the time for formwork removal.

2019-11-26 -

Application of Concrete Formwork Technology in Construction IV

Demolition of the concrete formwork is also part of the application of the concrete formwork technology. In the process of removing the formwork, it is necessary to test and analyze the demolding strength of the concrete to ensure the concrete strength is ≥1.2MPA, and then the removal work is carried out.

2019-11-25 -

Application of Concrete Formwork Technology in Construction III

Concrete formwork technology is widely used in the construction of the main body of the building. The concrete formwork mainly refers to the formwork formed by the newly poured concrete after forming, and also includes the complete set of structural systems supporting the formwork, because the classification form of the concrete formwork is different. Therefore, the problems that need to be paid attention to in technical applications are also different. The quality strength of concrete formwork also has a direct impact on the practical application of concrete formwork technology.

2019-11-25 -

Application of Concrete Formwork Technology in Construction Ⅱ

With the continuous improvement of China’s economic development level, the construction industry is also developing rapidly. In the process of implementing concrete construction projects, it is necessary to select reasonable construction plans and construction techniques to fundamentally ensure the efficiency of project construction. When building the main body of the building, the concrete formwork technology is used to first make the concrete formwork panels, and the relevant parts are also measured.

2019-11-25 -

Application of Concrete Formwork Technology in Construction Ⅰ

In the process of continuous economic development, the degree of urbanization has deepened, and the process of urbanization is also accelerating, which has effectively promoted the development of China’s construction engineering industry. In the process of building construction, due to the changing structure of the building and the overall architectural form, the construction of the main body of the project has brought certain difficulties. To effectively solve the related problems in the construction of the main building, it is necessary to apply full concrete formwork technology. On the basis of this article, we mainly study and analyze the implementation points and technical methods of concrete formwork technology in combination with the relevant requirements of construction in building the main body, and comprehensively and effectively improves the construction level and guarantees the quality of the project.

2019-11-22 -

Different Types Of Pipe Tee

The pipe tees can be used in a variety of industries, and can be divided into the following categories by different types: 1. By the production method, the pipe tee can be divided into the top system, pressing, forging, casting and so on. 2. According to the manufacturing standards, it can be divided into national standard, electric standard, water standard, American standard, German standard, Japanese standard, and Russian standard.

2019-11-22 -

Difference between SSAW Steel Pipe and LSAW Steel Pipe

SSAW steel pipe, whose full name is Straight seam submerged arc welding pipe. Longitudinally Submerged Arc Welded Steel pipes, which is abbreviated as LSAW steel pipe. These two types of pipes only have one letter’s difference, but they are truly different in their manufacturing process. Besides the manufacturing process, there are also other different aspects of these two types of pipe.

2019-11-21

Live Chat

Live Chat