ADTO News

-

Application Analysis of Construction Technology of Building Formwork (6)

The construction process quality and construction efficiency of the building formwork project is closely related to the professional quality level of the construction personnel. The correct construction method can improve efficiency and ensure the safety of the construction personnel. Therefore, improving the professional quality of construction workers is the current focus of work.

2019-11-21 -

Application Analysis of Building Formwork Construction Technology (5)

The correct selection of the construction technology of the building formwork is very important. It is necessary to select the appropriate process that meets the construction requirements according to the different conditions of the project and the actual conditions of the construction site to achieve the best use effect.

2019-11-20 -

Application Analysis of Building Formwork Construction Technology (4)

The construction of the formwork structure involves various construction links, therefore, it is not only necessary to use the formwork design drawing as the standard, but also to combine the overall construction process design drawings to ensure that the formwork configuration is in line with the overall construction requirements. At the same time, it is necessary to check the specification model, size and shape of the template to ensure the scientific and rational internal structure, which is also a key point to ensure the stability and reliability of the building.

2019-11-20 -

Performance Comparison of Aluminum Formwork and Wooden Formwork

For your better understanding of the performance difference of aluminum formwork and wooden formwork, we made a list as follows.

2019-11-20 -

Benefits and Applications of Square Tubing

Square tubing is commonly used for industrial purposes as it can provide numerous benefits. Industries value square tubing for its strength and ability to withstand extremes of temperature, pressure and destructive elements. While in domestic settings, square tubes are used in appliances, pipes, and fencing. Here are just a few of the many benefits and applications of square tubing.

2019-11-19 -

Application Analysis of Building Formwork Construction Technology(3)

The material quality of the formwork is extremely important for the construction process of the building formwork, which determines the efficiency and quality of the construction, so the relevant personnel should pay attention to this.

2019-11-18 -

Application Analysis of Building Formwork Construction Technology(2)

Before the construction of the building formwork project, the effect of the formwork after the construction should be simulated according to the design plan. The main purpose of this process is to ensure that the overall construction effect will not be affected by the pressure of the heavy objects and also determine the quality and efficiency of the formwork construction.

2019-11-15 -

Pipe Diameter VS Tube Diameter

Steel tube is generally used for structural purposes and the OD is an important and exact number. Steel tube size is specified by OD and the wall thickness, and the measured OD and stated OD are generally within very close tolerances of each other. Steel tube is usually more expensive than the steel pipe due to tighter manufacturing tolerances. Interestingly, while the stated and measured OD’s of steel tubes are almost exact most of the time, steel tube generally has a measured OD that is 1/8” larger than stated OD.

2019-11-15 -

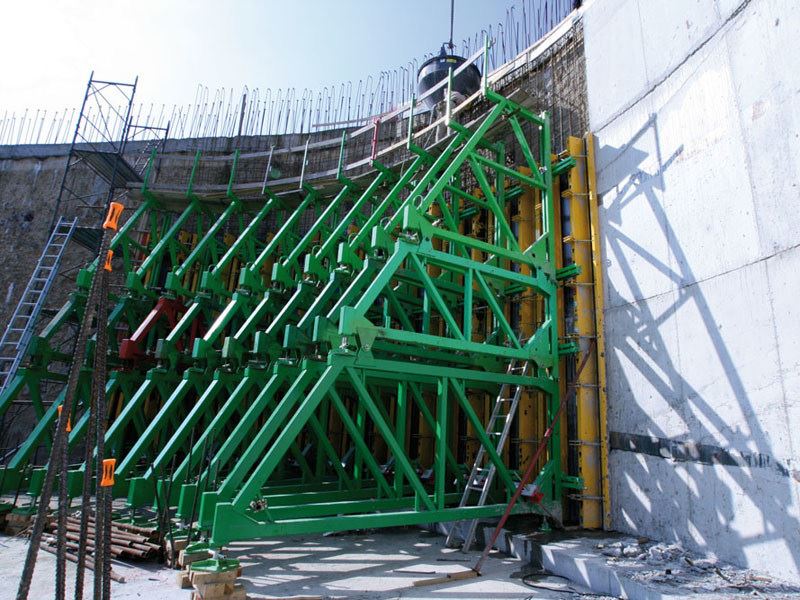

Application Analysis of Building Formwork Construction Technology

Construction formwork is an important part of the modern architectural industry, which determines the quality of the building and its overall stability. Another name of the formwork is mold. Formwork is formed in the actual construction application of building materials. After the use, the formwork is usually removed. That’s what we called formwork the building material with a strong temporary nature.

2019-11-15 -

What are the Advantages and Disadvantages of Aluminum Formwork?

The cost of formwork accounts for a little portion of the construction cost. While the formwork is the most space-saving and cost-effective turnover material. It is really a good choice to use formwork in construction projects.

2019-11-14 -

What is the Socket Tee?

The socket tee is mainly a high-pressure three-way pipe connecting fitting which is formed by forming a round forged steel or steel ingot and then forming it by a lathe machine.

2019-11-13 -

Welding Process of ERW Steel Pipes

Several electric resistance welding (ERW) processes are available for ERW steel tube and ERW steel pipe production. While each process has different characteristics, all ERW processes have one thing in common–all of them produce a forged weld.

2019-11-13 -

What Is a Steel Tee?

The steel tee is a pipe fitting and a pipe joint. Used to change the direction of the fluid, used in the branch pipe of the main pipe.

2019-11-12 -

What Is A Lateral Tee?

A lateral tee is one kind of tee fittings, which has a 45-degree branch from a pipeline: (45° Lateral Tee). It is a kind of steel pipe tee, but the branch direction is different from the straight tee. On the contrary to the lateral tee, the straight tee has a branch pipe direction of 90 degrees to the run pipe.

2019-11-12 -

What is An Equal Tee?

Equal-diameter tee is widely used in the construction and maintenance of petrochemical, oil and gas, liquefied petroleum gas, chemical fertilizer, power plant, nuclear power, shipbuilding, papermaking, pharmaceutical, food hygiene, urban construction, and other industries. In the industry, the pressure of such pipe fittings is relatively high, the maximum pressure can reach 600 kg, and the water pressure in the living is low, generally 16 kg.

2019-11-12

Live Chat

Live Chat