ADTO News

Common Types Of Flange: Slip-on Flange

Slip-On Flange can be made from a number of different materials depending on the piping material and the requirements of the application. Selection depends on factors such as environmental corrosion, operating temperature, low pressure, and economy. Some of the most common materials include carbon steel, alloy steel, stainless steel, cast iron, copper, and PVC.

The calculated strength from a Slip-On flange under internal pressure is of the order of two-thirds that of Welding Neck Flanges, and their life under fatigue is about one-third that of the latter.

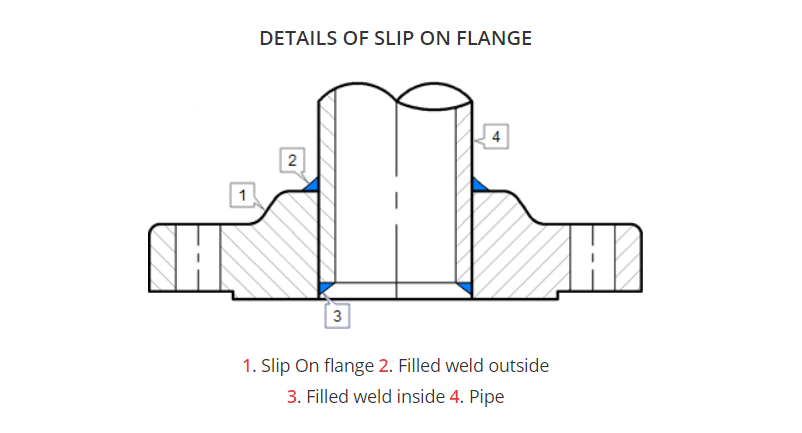

The connection with the pipe is done with 2 fillet welds, as well at the outside as also at the inside of the flange.

The X measure on the image is approximate:

Wall thickness of pipe + 3 mm.

This space is necessary, to do not damage the flange face, during the welding process.

A disadvantage of the flange is, that principle always firstly a pipe must be welded and then just a fitting. A combination of flange and elbow or flange and tee is not possible, because named fittings have not a straight end, that complete slid in the Slip On Flange.

Live Chat

Live Chat