ADTO News

Common Types of Flange: Welding Neck Flange

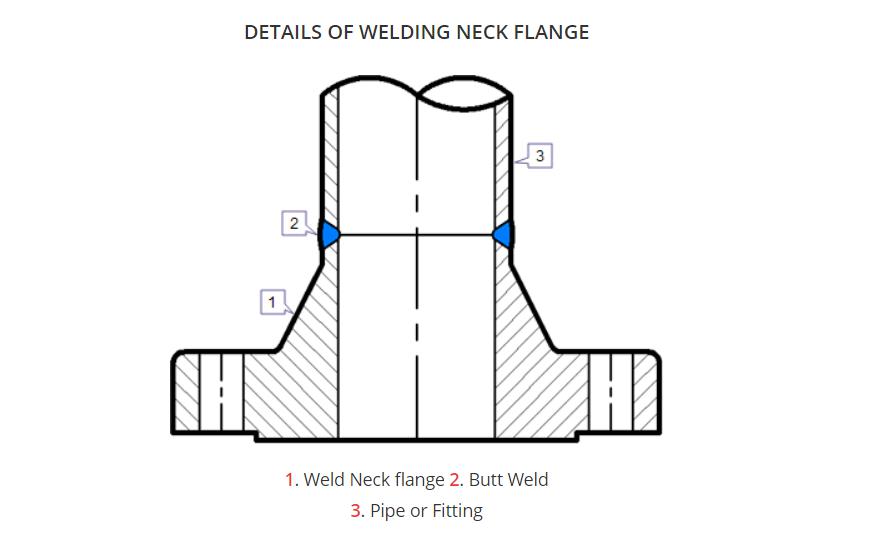

As already described before, the most used flange types ASME B16.5 are Welding Neck Flange, Slip-On Flange, Socket Weld Flange, Lap Joint Flange, Threaded and Blind flange. Today, we ADTO GROUP want to introduce the Welding Neck Flange, completed with a detailed image.

Welding Neck Flanges are easy to recognize at the long tapered hub, that goes gradually over to the wall thickness from a pipe or fitting.

The long tapered hub provides an important reinforcement for use in several applications involving high pressure, sub-zero and/or elevated temperatures. The smooth transition from flange thickness to pipe or fitting wall thickness effected by the taper is extremely beneficial, under conditions of repeated bending, caused by line expansion or other variable forces.

These flanges are bored to match the inside diameter of the mating pipe or fitting so there will be no restriction of product flow. This prevents turbulence at the joint and reduces erosion. They also provide excellent stress distribution through the tapered hub and are easily radiographed for flaw detection.

This flange type will be welded to a pipe or fitting with a single full penetration, V weld (Buttweld).

Live Chat

Live Chat