ADTO News

-

Choosing the Right Formwork System for Your Project

Selecting the appropriate formwork system is a key decision that affects construction speed, concrete quality, labor efficiency, and overall project cost.

2025-11-14 -

A Complete Overview of the Formwork Construction Process

In the construction world, formwork is a crucial element that provides the necessary support and structure for concrete pours. Understanding the formwork construction process is essential for ensuring the integrity and quality of your projects.

2025-08-06 -

Understanding Construction Formwork and Best Practices for Success

Construction formwork is a crucial element in the building process, serving as a temporary structure that shapes and supports concrete until it hardens.

2025-06-04 -

What is Climbing Formwork?

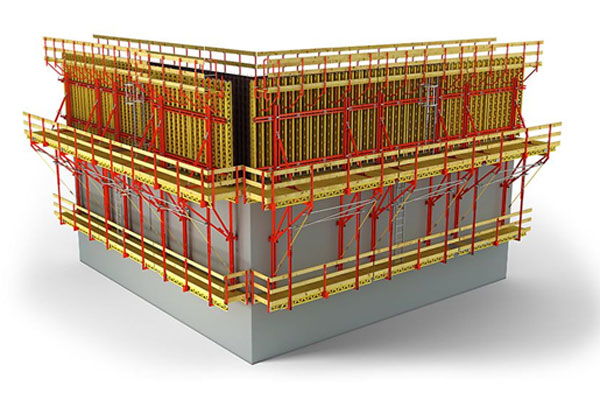

Climbing formwork is a special type of formwork for large vertical concrete structures. Climbing formworks represent an effective solution for structures that require seamless walls or have a very repetitive form.

2022-08-30 -

What Are the Differences Between Steel Formwork and Aluminum Formwork?

Steel formwork and aluminum formwork are both considered general types of engineered formwork. Engineered formwork and conventional formwork are the two main categories of formwork. Conventional formwork is typically made from timber, while engineered forms are made from steel, aluminum, or plastic. Timber formwork costs a bit less, but it’s not as durable and rigid. It also can’t be re-used and re-sold numerous times after its initial use, like engineered formwork.

2021-09-29 -

Build The Marvels Architecture With Brilliant Shuttering

The Shuttering’s history can be date back to the Roman Era. The arches, domes, and vaults of that period were supported by shuttering formwork built in the form of the final construction. With the increasing requirements of mass construction, shuttering needs to be efficient, modular, replicable, and fast to the mantle and dismantle. And the obvious way to do that was by making them molds in regular geometrical forms. This way shuttering has been one of the drivers of the modern geometric design aesthetic.

2021-06-10 -

ADTO Formwork Technology Efficiently Helps Construct High-Quality Buildings

Formwork technology is constantly evolving to keep pace with the fast-changing demands of the construction sector. ADTO Formwork is the latest formwork trend in the international construction field.

2021-06-07 -

Comparison of Steel Formwork And Plastic Formwork

Plastic formwork is a product with characteristics of energy-saving and environmental friendly. It is one of the direction of the development of construction industry in the future. Plastic formwork is made of fiber high-strength plastic. When the raw materials are in the molten state, the plastic formwork is single molding shaped with shooting technique. Plastic formwork has advantages of simple craft, light weight, low cost, and circular use. It has the same mechanical properties as the steel formwork. Plastic formwork has a broad development prospect as it can replace the steel formwork in the construction industry for most purposes. Below we will make a comparison between plastic formwork and steel formwork as shows below.

2020-09-17 -

Types of Formwork Used in Concrete Construction

Concrete is one of the most popular building materials as it’s safe, durable, sustainable, and economical. Formwork is an essential material used in concrete construction. Formworks are temporary or permanent molds that cannot be removed until the concrete is shaped into the designed structure.

2020-08-13 -

Modern Formwork System Classification

Formwork is a kind of molds used to shape the freshly poured concrete or some other similar materials. It is widely used in the construction industries. With the hundreds of years developing, formwork has been developed from timber formwork to metal formwork (in this passage, we will talk about steel formwork and aluminum formwork), and plastic formwork. In our modern society, metal formwork and plastic formwork are mostly used in construction projects. Today, we are going to talk about something about the modern formwork system classification.

2020-07-07 -

Formwork Types and Its Application In Construction

Construction formwork, also known as shuttering, is a permanent or semi-permanent structure used to support the construction building being erected. The formwork consists of concrete that is poured and hardened to withstand all types of loads. It should be properly braced both vertically, and diagonally so that it keeps its form and structure. It should be set accurately, be as light as possible with waterproof joins so that no swelling or movement occurs.

2020-04-27 -

Requirements On Formwork System To Guarantee The Safety of Workers

The fulfillment of the below requirements would guarantee a safe, strong, and robust formwork system and provide safe working conditions for laborers. Formwork is a temporary mold into which fresh concrete and reinforcement are placed to form a particular reinforced concrete element. It supports part or the whole of a permanent structure until it is self-supporting.

2020-04-16 -

Technical & Functional Requirements On Formwork System

There are several requirements that the formwork system needs to meet, otherwise, it would not serve its purpose adequately. In order to make sure that the formwork system fulfills its design goals, the designer and site engineer should take technical, functional requirements of the formwork into consideration.

2020-04-16 -

Do You Know the Components of Table Formwork System?

Table Formwork System is a kind of shuttering specializing in floor concreting and it is widely used in high building and skyscraper, multi-layer industrial factory building, substructure, etc. Table formwork system has a simple structure, it is easy to assemble and disassemble and can be reusable.

2019-12-06 -

Different Types of Table Formwork System

There are three types of table formwork system as follows.

2019-12-04

Live Chat

Live Chat