ADTO News

-

Demolition of Cast-in-place Frame Structure and Column Formwork

The removal procedure of cast-in-place frame structure and column formwork

2019-11-27 -

General Requirements For Formwork Removal

Here we listed the detailed requirements for the removal of formwork as follows.

2019-11-26 -

What’s the Time Should the Formwork Be Removed During Construction?

What’s the time should the formwork be removed during construction? We have written this passage to help you better understand the hardening of the concrete and the time for formwork removal.

2019-11-26 -

Application of Concrete Formwork Technology in Construction IV

Demolition of the concrete formwork is also part of the application of the concrete formwork technology. In the process of removing the formwork, it is necessary to test and analyze the demolding strength of the concrete to ensure the concrete strength is ≥1.2MPA, and then the removal work is carried out.

2019-11-25 -

Application of Concrete Formwork Technology in Construction III

Concrete formwork technology is widely used in the construction of the main body of the building. The concrete formwork mainly refers to the formwork formed by the newly poured concrete after forming, and also includes the complete set of structural systems supporting the formwork, because the classification form of the concrete formwork is different. Therefore, the problems that need to be paid attention to in technical applications are also different. The quality strength of concrete formwork also has a direct impact on the practical application of concrete formwork technology.

2019-11-25 -

Application of Concrete Formwork Technology in Construction Ⅱ

With the continuous improvement of China’s economic development level, the construction industry is also developing rapidly. In the process of implementing concrete construction projects, it is necessary to select reasonable construction plans and construction techniques to fundamentally ensure the efficiency of project construction. When building the main body of the building, the concrete formwork technology is used to first make the concrete formwork panels, and the relevant parts are also measured.

2019-11-25 -

Application of Concrete Formwork Technology in Construction Ⅰ

In the process of continuous economic development, the degree of urbanization has deepened, and the process of urbanization is also accelerating, which has effectively promoted the development of China’s construction engineering industry. In the process of building construction, due to the changing structure of the building and the overall architectural form, the construction of the main body of the project has brought certain difficulties. To effectively solve the related problems in the construction of the main building, it is necessary to apply full concrete formwork technology. On the basis of this article, we mainly study and analyze the implementation points and technical methods of concrete formwork technology in combination with the relevant requirements of construction in building the main body, and comprehensively and effectively improves the construction level and guarantees the quality of the project.

2019-11-22 -

Application Analysis of Construction Technology of Building Formwork (6)

The construction process quality and construction efficiency of the building formwork project is closely related to the professional quality level of the construction personnel. The correct construction method can improve efficiency and ensure the safety of the construction personnel. Therefore, improving the professional quality of construction workers is the current focus of work.

2019-11-21 -

Application Analysis of Building Formwork Construction Technology (5)

The correct selection of the construction technology of the building formwork is very important. It is necessary to select the appropriate process that meets the construction requirements according to the different conditions of the project and the actual conditions of the construction site to achieve the best use effect.

2019-11-20 -

Application Analysis of Building Formwork Construction Technology (4)

The construction of the formwork structure involves various construction links, therefore, it is not only necessary to use the formwork design drawing as the standard, but also to combine the overall construction process design drawings to ensure that the formwork configuration is in line with the overall construction requirements. At the same time, it is necessary to check the specification model, size and shape of the template to ensure the scientific and rational internal structure, which is also a key point to ensure the stability and reliability of the building.

2019-11-20 -

Performance Comparison of Aluminum Formwork and Wooden Formwork

For your better understanding of the performance difference of aluminum formwork and wooden formwork, we made a list as follows.

2019-11-20 -

Application Analysis of Building Formwork Construction Technology(3)

The material quality of the formwork is extremely important for the construction process of the building formwork, which determines the efficiency and quality of the construction, so the relevant personnel should pay attention to this.

2019-11-18 -

Application Analysis of Building Formwork Construction Technology

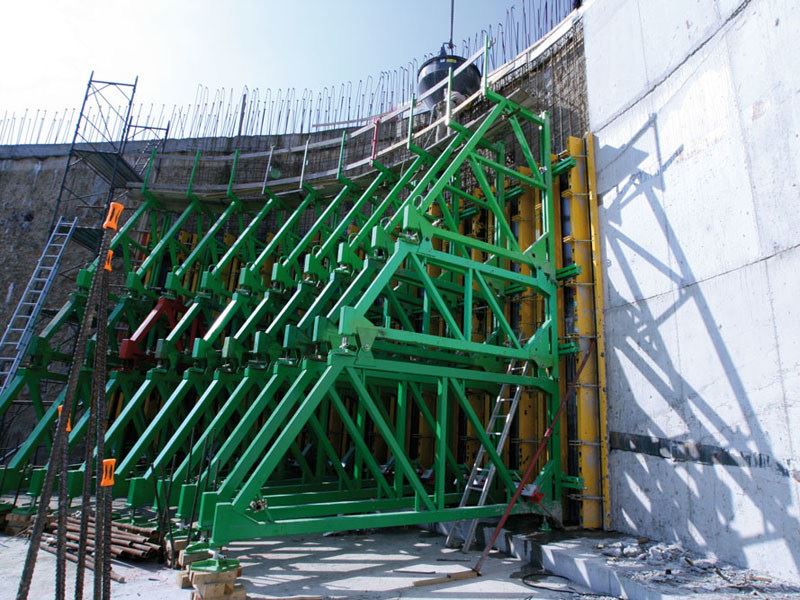

Construction formwork is an important part of the modern architectural industry, which determines the quality of the building and its overall stability. Another name of the formwork is mold. Formwork is formed in the actual construction application of building materials. After the use, the formwork is usually removed. That’s what we called formwork the building material with a strong temporary nature.

2019-11-15 -

On Construction Project, How to Set Good Safety Plan for Concrete Formwork System?

Good safety plans for the formwork system ensure execution of construction project as per established construction practice and avoid undesired events such as failure of formwork and consequent delay in construction and possible loss of life. Commonly, safety shall begin in the planning and management of a project.

2019-10-10 -

How to Achieve Economy in the Cost of Formwork Construction?

The reduction of formwork construction is essential in declining the total cost of the project because it accounts for up to 60% of the entire cost of the concrete structure. Decision made at the design phase can play a crucial role in this regard. New materials, accessories, and prefabricated formwork components may enable designers to achieve their design goals at a lower cost.

2019-10-08

Live Chat

Live Chat