ADTO News

-

Differences Between Casing Coupling and Tubing Coupling

There are couplings for casing and couplings for tubing, the function is the same that to connect the pipe to each other. On the other hand, still, there are some differences between the two.

2020-03-03 -

How Many Types For the API Couplings?

There are several types covered in API 5CT standard for coupling specifications, classified in regular couplings, special clearance couplings, combination couplings, reducing couplings, seal ring couplings, and special bevel tubing regular couplings.

2020-03-02 -

Effects of Three Kinds of Chemical Elements on Steel

What is the Carbon (C) effect on steel material? Carbon is the most important element found in steel material. Steel material mechanical strength is directly connected with carbon content. When the carbon element content increased, yield point and tensile strength increased, but the plasticity and impact reduced. In the case of carbon content more than 0.23%, steel welding performance will get worse.So in the low alloy steel structural, to get better welding performances, the carbon content usually less than 0.2%.

2020-02-28 -

Characteristics and Advantages of ADTO Rebar Connecting System

Rebar Connection System is a high quality, economical connection system of reinforcement. The ADTO Rebar Connection System is a simple, efficient method for connecting reinforcement steel, which eliminates the disadvantages of the traditional procedure of lapped joints. The lapped joints system may provide long-term consumption, greater rebar congestion and unsafe usage in seismic zones.

2020-02-27 -

Five Kinds of Products Ends

Flat-end pipe Flat end pipe is a pipe supplied with unmachined threads, and It may upset or not , but it shall comply with all requirements of a specific steel grade in this standard.

2020-02-22 -

Do You Know the Regulations on the Pipe Defects?

According to the below regulations, we can learn that all pipes and fittings made of pipes shall not have the following defects:

2020-02-21 -

Do You Know the Heat Treatment Methods for API 5CT?

The Heat treatment methods for API 5CT casing and tubing is an important factor to differ each grade. Products requiring heat treatment shall be subjected to full body and full length heat treatment. The heat-treated upsetting product should be heat treated full body, full length after upsetting.

2020-02-20 -

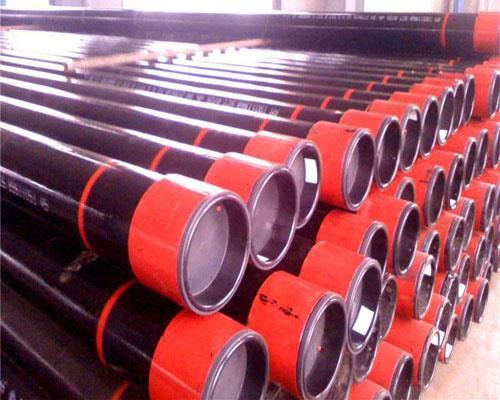

What is API 5CT Casing & Tubing Specification?

API 5CT is standard technical specifications for steel casing and tubing pipes used for oil wells in petroleum and natural gas industries.

2020-02-19 -

What Advantages Does Galvanized Scaffolding Planks Have?

The traditional wooden scaffolding plank is easy to crack, corrosion, easy to burn and has safety hazards. The angle steel mesh board is easy to rust and fall off. While galvanized scaffolding plank manufactured by ADTOMALL is provided with arranged convex holes. High anti-skid coefficient, good effect, safe and guaranteed.

2020-01-18 -

What Characteristic Does Scaffolding Coupler Have?

Scaffolding coupler can be generally divided into the following categories: double coupler, swivel coupler, and sleeve coupler. Among the construction steel pipe connection coupler, the double coupler is the most used scaffolding coupler. Use approximately one right-angle coupler per meter of steel tube. The connecting coupler is the intermediate connecting part between the steel pipe and the steel pipe. The connecting coupler has good performance and a tendency in actual construction.

2020-01-18 -

Is the Ringlock Scaffolding a Good Scaffolding System?

In order to meet the market requirements, ring lock scaffolding manufacturers are continuously researching & develop and design new products, supplying the best ringlock scaffolding to the construction industry. As for now, the most popular scaffolding system used in the construction industry is ringlock scaffolding. Ringlock scaffolding is the result of introducing European advanced manufacturing technology.

2020-01-17 -

Why Construction Manager Choose to Use Aluminum Alloy Formwork?

The aluminum formwork system is composed of aluminum alloy plates. After the system assembly, a whole frame is formed. The bearing capacity of aluminum alloy formwork is up to 30-40kn per square meter.

2020-01-17 -

Why We Choose Aluminum Alloy Formwork For Construction?

The aluminum alloy formwork can guarantee the construction quality and reduce the dependence of construction quality on workers' technical level. The construction effect is good, the geometry dimension is accurate, the concrete surface is smooth and smooth after the mold is removed, can achieve or close to the effect of the clear water wall, can reduce or eliminate the second plastering operation, reduce the cost of the builder's plastering.

2020-01-17 -

The Merits of Using Aluminum Alloy Formwork

It weighs less than 19Kg per square meter. The steel formwork weighs 60kg per square meter, while the aluminum formwork weighs less than 20kg. It can be assembled and transferred manually, without relying on hoisting machinery, with wide adaptability, which can reduce the operation cost of tower crane, and the construction without nails can avoid the injury of hands and feet.

2020-01-17 -

Environmental Protection Merits of Using Aluminum Alloy Formwork

In the aspect of environmental protection, aluminum alloy formwork also has rare advantages:

2020-01-16

Live Chat

Live Chat