ADTO News

-

Why Do We Choose to Use Rebar Couplers Instead of Lapped Joints?

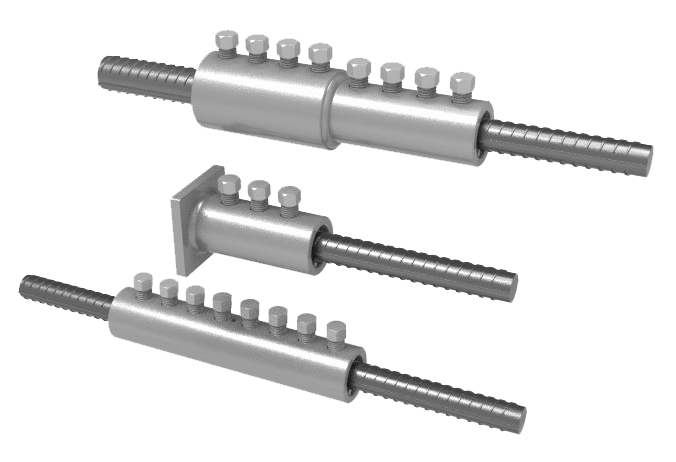

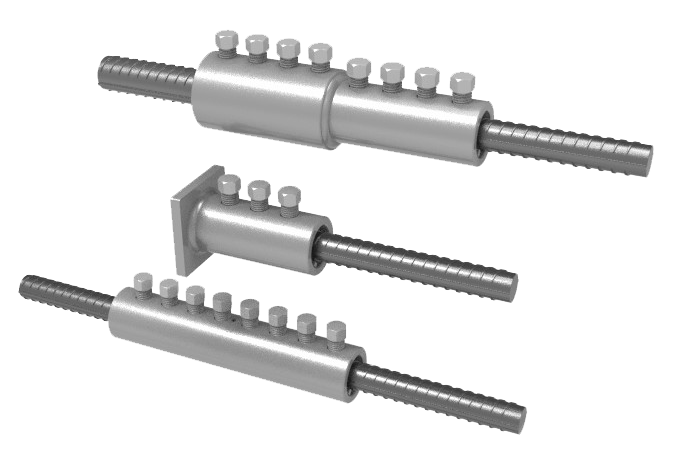

Rebar couplers, also named mechanical rebar connections, also known as mechanical splices, are used to join lengths of rebar together. Reinforcing bar coupling has all of the features desirable in a rebar joining system combined with unequaled simplicity of installation. Couplers are designed to splice the same diameter bars where one bar is free to move and can be rotated. Mechanical connections between two pieces of rebar that enable the bars to behave in a manner similar to continuous lengths of rebar. Why do we choose to use rebar couplers in the construction project?

2020-04-10 -

Common Faults of Flanges

In the continual production of the modern industry, it is common that flanges have some problems. For example, leakage, due to various influencing factors such as corrosion of media, erosion, temperature, pressure, vibration, etc. Causes including the processing error in the sealing surfaces' size of flanges, the aging of the sealing components and improper installation will easily lead to the occurrence of leakage.

2020-04-09 -

Do You Know the Test Steps of Couplers?

Do you know the test steps of couplers? Today we will have a brief discussion of it.

2020-04-09 -

How to Solve the Common Faults of Flanges?

Some common faults of flanges are listed as the following.

2020-04-08 -

What is the Classification of Flanges & Difference Between Orifice Flanges and Other Flanges?

Flanges can be divided into threaded flanges and welded flanges. Threaded flanges are used for low pressure and small diameter circumstances while welded flanges are used for high pressure and large diameter circumstances. The thickness of the flanges of different pressures and the diameter and number of connecting bolts are different. Depending on the level of pressure, the flange gaskets are also varied from low or high-pressure asbestos gaskets to metal gaskets. Connecting with flanges are easy to operate and can withstand large pressures.

2020-04-08 -

What Factors Should Be Paid Attention to During Flange Installation?

In order to ensure that the installed flange will not cause oil leakage, what factors should be paid attention to during flange installation? First, the flange should have sufficient strength and should not be deformed when tightened during the flange installation. The flange sealing surface should be clean, and the oil and rust should be carefully removed during flange installation.

2020-04-07 -

Do You Know The General Knowledge of Flanges?

For people who know little about flanges, flanges are just disk-shaped metal parts. They don’t know how to use flanges and what is the function of flanges. Actually, the flange is a common pipe fitting that helps connect pipes, equipment, etc. Today, we will introduce the general knowledge of flanges to you.

2020-04-07 -

The Advantage and Manufacturing Process of Thread Rebar Splicing Coupler

#1 No reducing of rebar cross-sectional area #2 Pass elongation test #3 Easy installation, no need torch wrench. #4 One coupler can meet all connection requirement #5 Manufactured under ISO 9001 standard and same strict quality guarantee. Tested by the third party. #6 Full traceability of raw material and production batch. #7 Tested under several cyclic situations #8 No bar conjunction problem happens. #9 No large quantity of bars required.

2020-04-03 -

Different Kinds of Rebar Splice For Rebar Connection

Today, we are going to discuss different kinds of rebar splice. Below we will make a brief introduction about these rebar couplers.

2020-04-02 -

The Growing Demands on Plastic Formwork in Next Decade

As the UN estimates 3 billion housing units needed by 2030, there will be a growing need for mass housing. The future of residential construction is marked by a rapidly growing demand for cost-effective, simple housing in developing and emerging countries, estimated to reach 3 billion housing units by 2030. This immense construction calls for innovative solutions and motivated ADTO GROUP to increase awareness of its cellular light-weight concrete plastic formwork solutions.

2020-04-01 -

Matters Need Attention Before The Installation Of Rebar Couplers

For best installation and performance, try to adjust the orientation of the rebar coupler so that the circular deformations of the rebar are in full bearing contact with the wedge shape of the coupler body, opposite of the screws. Prior to assembly, straighten excessively bent rebar ends so that proper wedge contact is made between rebar and coupler. BAR ENDS should be straight. For curved rebar with a diameter that exceeds 54 feet, a bar end straightness check is not necessary. If needed, grind-off large shear lips that prevent proper insertion of rebar into the coupler.

2020-03-31 -

Things You Need to Consider While Buying Rebar Coupler

Rebar coupler is a widely used construction material all around the world. Do you know where to buy a high-quality rebar coupler and how to buy a rebar coupler? Here are some of the important features of the rebar coupler which you must consider before buying the best quality rebar coupler.

2020-03-31 -

Where to Get the Best Rebar Coupler For Reliable Rebar Connection?

Do you want to know where you can find the best and highly reliable rebar coupler? There ADTOGROUP can be one of the most amazing places for you to buy the best rebar coupler for your upcoming construction project.

2020-03-27 -

How to Install Rebar Connection Coupler?

Rebar Connection Coupler (below abbreviated as rebar coupler) is a kind of connecting system used to joint reinforcement bars. Rebar coupler is extensively used in construction projects all around the world. But do you know how to install rebar connection system? The rebar coupler installation process can be divided into the following steps:

2020-03-26 -

What is Thread Rolling in Modern Manufacturing Industry?

Thread rolling, in modern manufacturing, has an extremely high productivity rate, significantly higher than producing threaded parts by machining. Machining is the alternative method for industrial manufacturing of threaded parts. Producing threads by this method has several other benefits over machining. Forming will harden the metal through cold working, does not waste material by cutting, and produces a favorable grain structure to strengthen the part with respect to its function.

2020-03-25

Live Chat

Live Chat