ADTO News

-

Do You Know What is Thread Rolling?

Thread rolling is a metal rolling process used extensively in the manufacturing industry to produce screws, bolts, and other fasteners. Thread rolling is a preferred method for producing strong, smooth, precise, and uniform external thread forms. Thread rolling is different from other types of threading processes like cutting, grinding, and chasing. A common thread rolling process, used in industry to manufacture threaded parts, involves forming the threads into the metal of a blank by a pressing and rolling action between two dies. The die surfaces hold the shape and the force of the action forms the threads into the material. A similar metal forming process has been developed for the production of gears.

2020-03-24 -

ADTO Thread and Profile Rolling Machines

Engineering innovations and experience led to advantages in cold rolling thread manufacturing technology. There are useful processes and machines for nearly every rotation-symmetric profile today. The ADTO Thread Rolling Machines are outstanding in terms of workpiece quality requirement, the possibility of connection to an automated handling system and output.

2020-03-23 -

What Are Tapered Thread Couplers?

ADTO Tapered Thread couplers are suitable for the majority of construction projects applications that require the connection of rebars. They are normally supplied fitted to the end of the threaded bar and require only the engagement and tightening of the adjoining bar on-site using a calibrated torque wrench.

2020-03-20 -

ADTO Rebar Connection System

The Rebar Connection System is the most effective method of connecting reinforcement steel, which overcomes the disadvantages of the traditional methods as overlap and welding of the reinforcement steel.

2020-03-18 -

Do You Know The Manufacturing Process of LSAW Steel Pipe?

The LSAW large-diameter steel pipe manufacturing process is explained in the steps below:

2020-03-17 -

What’s The Meaning of LSAW Steel Pipe And What Is The Feature Of It?

LSAW steel pipe is the abbreviation of the LSAW (Longitudinal double submerge arc welding) carbon steel pipe. It is a type of SAW pipe made of steel plates that were hot rolled by JCOE or UOE forming technology. JCOE technology represents the shaping and forming processes involved during manufacturing as well as the inner and outer welding and cold expansion carried out after welding.

2020-03-16 -

What Standards Referred to Carbon Steel Plate?

The carbon steel plate almost includes all the common standards of steel plate/sheet.

2020-03-13 -

Different Types Of Carbon Steel Plates And Their Usage

Below there are Different Types Of Carbon Steel Plates And Their Usage.

2020-03-12 -

Things You Should Know About Carbon Steel Plate

A carbon steel plate is usually considered as a kind of steel plate that does not contain much alloy steel elements. The alloy steel elements are generally C, Mn, P, S, Si. Besides these, there are no minimum limits for elements of Al, Cr, Ni, Mo, V, etc.

2020-03-12 -

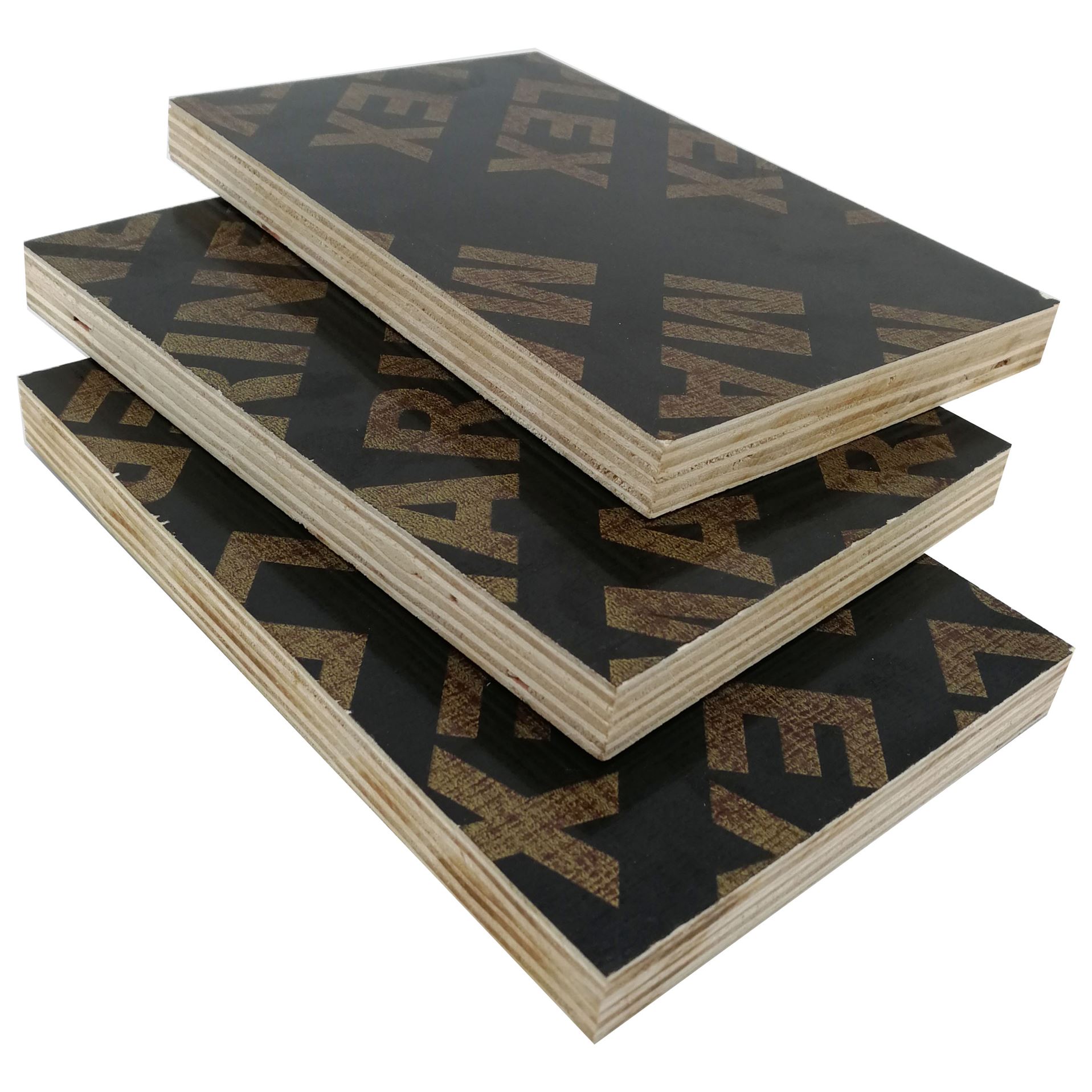

Why ADTO Plywood is Competitive in Global Market?

As we all know China now produces half of the world’s plywood of all kinds, including commercial plywood and film faced plywood. But as a country that is not abundant in wood resources, you might all wonder how can China did it. There are a bunch of reasons and here we are going to explain why your plywood supplier in China has an advantage.

2020-03-11 -

What is the Meaning of WBP in Plywood Industry?

Plywood is widely used in construction projects around the world. But there‘s really a few people know the true meaning of the word “WBP”. WBP stands for “Water Boiled Proof”. If you use WBP glue for the plywood/film faced plywood, the panel will be exposed to humid or moisture for a long time without delamination. As the word of “MR”, WBP is not the name of a specific glue but a kind of property of glue. If glue has WBP property, the glue will be called WBP glue. The melamine-formaldehyde and phenolic-formaldehyde can be regarded as WBP glue as the plywood made from these are water boil proof.

2020-03-11 -

Do You Know What is Film Faced Plywood and its Advantages?

Film faced plywood, also named concrete plywood, form ply or marine plywood. Film faced plywood is widely used in modern building projects especially those that need lots of cement work. It’s regarded as an important part of the formwork.

2020-03-10 -

Differences Between Socket Welding Fitting And Butt Weld Fittings

In the case of socket welding (SW) fittings, the referred standard is ASME B16.11. Here, a pipe could be inserted into a recessed area of the fitting. Both the fitting and the pipe shall be square cut and do not require any preparation or beveled end other than cleaning the outside. This will easy the installation and welding processes. As for butt weld (BW) fittings, the referred standard is ASME B16.9. with their ends being welded on to the pipe end, the thickness would be the same as those of pipes. In this case, the end of the fittings could be beveled.

2020-03-09 -

Advantages and Disadvantages of Socket Weld Fittings

Socket weld fitting is a widely used pipe fitting. Do you know the advantages and disadvantages of socket weld fittings? Today we will have a discussion on the advantages and disadvantages of socket weld fittings.

2020-03-06 -

What is Socket Weld Pipe Fittings?

As we all know that there are four connecting types for the pipe fittings: Socket weld, butt weld, threaded, and flanged. In terms of steel pipe fittings that you would be able to use for your pipeline projects, you will find two of them to be quite popular: Socket weld fittings and butt weld fittings.

2020-03-05

Live Chat

Live Chat