ADTO News

-

Why Scaffolding Safety Is So Essential?

Nowadays, scaffolding is a valuable construction equipment that is used in many construction projects. The main function of scaffolding is to support workers and construction materials when working at heights. As we know, safety is critical to all construction jobs, so obviously there are strict rules need to be abiding by when working with scaffolding. There are some scaffolding safety tips mentioned below will surely help you:

2020-05-07 -

The Major Benefits Of Using Aluminum Ladders

Have you ever used timber ladders? If the answer is yes, you may know how tiring it is for moving the timber ladder. The timber ladders’ complexity changes a simple job into a complex one. Is there a remedy for the timber ladder? As for now, people have found that using lightweight and durable aluminum ladders is better than using timber ladders. There are many kinds of aluminum ladders. When buying aluminum ladders, you need to consider the best one that suits your requirements. In addition, you need to consider whether you need a step ladder, an extension ladder, or any of those multipurpose. Choosing aluminum ladders can be the best choice for you as the following reasons:

2020-05-06 -

Which Should be Considered When Buying Scaffolding Tower?

Once you’ve decided that you definitely need a tower, it’s time to make sure you hire or purchase the correct scaffold for the job. If you have a simple repairs job that’s in one spot you may be able to get a standard scaffolding tower that is erected on even ground and secured in the one spot. If, however, you need to be moving along a surface such as painting a ceiling or repairing gutters, you’re going to want to be able to move it without dismantling it first. In that case, a mobile tower with wheels on the bottom would be perfect. Don’t forget to also look at the length and width. Think carefully about how many people need to be working on it at once and if you need room for tools or materials whilst still being able to walk around.

2020-04-30 -

Things You Should Think Before Buying Scaffolding Tower

You may think that using a scaffolding tower for a small job is a little bit of an overkill. But once you really think about the ease of use, safety, and flexibility you’ll probably find that a scaffolding tower makes much more sense in the long run.

2020-04-30 -

Do You Know How to Choose The Right Scaffold?

When it comes to scaffolding choosing, it must be confusing for you to choose the right scaffolding. There are many factors to consider before choosing the type and design of scaffolding you require for the next construction project.

2020-04-30 -

Cuplock Scaffolding & Kwikstage Scaffolding

Cuplock scaffolding joints, with reasonable structure, simple manufacturing process, easy installation and disassembly, and wide application range, can fully meet the construction requirements of various kinds of buildings. Kwikstage scaffolding is a kind of widely used exterior wall scaffolding in Australia. Kwikstage scaffolding has a complete range of accessories. All parts required for various application scenarios are standardized and modularized. It has reasonable structure design and safe mechanical properties. Users can easily get started and become a master of erecting solutions. For example, there are 4 types of channel modules, 3 sizes of scaffolding, and wall-filling buckle plate, scaffolding plank can be fully laid in any direction parameter .etc.

2020-04-30 -

Suggestions Should Be Remember When Buying New Scaffolding

Scaffolding is a necessary tool in the construction industry. There are several factors should be considered when you purchase new scaffolding.

2020-04-29 -

How to Choose the Right Scaffolding Manufacturer?

There are many scaffolding manufacturers all over the world. Some manufacturers may offer you cheap prices and simple erecting structures. While others may offer you the best quality you need. When you’re looking for a scaffolding manufacturer, there is something you should bear in mind. There are many factors you may face when choosing the right scaffolding manufacturer for your construction project including Communication, Price, Qualifications, and Location of Factory.

2020-04-28 -

Formwork Types and Its Application In Construction

Construction formwork, also known as shuttering, is a permanent or semi-permanent structure used to support the construction building being erected. The formwork consists of concrete that is poured and hardened to withstand all types of loads. It should be properly braced both vertically, and diagonally so that it keeps its form and structure. It should be set accurately, be as light as possible with waterproof joins so that no swelling or movement occurs.

2020-04-27 -

Four Different Types of Stainless Steel

#1 Ferritic Stainless Steel Based on Chromium with small quantities of Carbon, ferritic stainless steel has a similar microstructure to both carbon and low alloy steels. Compared to other types of stainless steel, it is usually limited to the use of relatively thin sections, due to a lack of toughness in welds. Although, contractors use ferritic stainless steel for a wide range of applications that do not require welding. Additionally, you cannot harden ferritic steel with heat treatment. But you can use it in seawater or other aggressive conditions when you include the addition of Molybdenum. Ferritic stainless steel is also magnetic, but not as formable as austenitic stainless steel for example. On the other hand, steelworkers often choose ferritic stainless steel because of its resistance to stress corrosion cracking.

2020-04-26 -

The Difference Between 304 & 316 Stainless Steel

When selecting stainless steel that must endure corrosive environments, austenitic stainless steel is typically used. Possessing excellent mechanical properties, the high amounts of nickel and chromium in austenitic stainless steels also provide outstanding corrosion resistance. Additionally, many austenitic stainless steels are weldable and formable. Two of the more commonly used grades of austenitic stainless steel are grades 304 and 316. To help you determine which grade is right for your project, this passage will examine the difference between 304 and 316 stainless steel.

2020-04-26 -

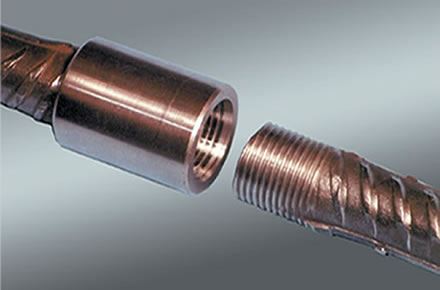

Do You Know What is Mechanical Rebar Splice?

A mechanical rebar splice is a joint or a coupler used to splice two rebars. The mechanical rebar splicing is a new type of splicing in the world construction industry. The mechanical rebar splice has many advantages compared to the conventional method of overlapping. A longer reinforcement bar is obtained through this rebar coupler splicing. The errors due to wrong lap length as in the conventional method are avoided. The wastage of steel is reduced. The use of a mechanical rebar joint helps to avoid lap length. This will save the appreciable amount of steel. We can use couplers as dowel bars. This will save the formwork material.

2020-04-24 -

What’s the Importance of Using Lap Rebar Splices?

The lap rebar splice is the most common and economic rebar splice used in the construction project. Compared to lap rebar splicing, the welded rebar splices and mechanical rebar splices require more labor and skill.

2020-04-24 -

Introduction of Tension and Compression Mechanical Splices for Rebars

This type of mechanical rebar splice can resist tension and compression stress. There are sizable numbers of commercially manufactured tension and compression mechanical splices for rebars. Tension and compression mechanical rebar splices types, designated bar sizes to be spliced by each splice type, the grade of the steel bar which is spliced using certain types of tension and compression mechanical rebar splice, and installation condition of each mechanical rebar splices are provided.

2020-04-23 -

What Are the Methods of Splicing Reinforced Bars?

Most of the reinforced concrete structures won’t be provided with full-length rebars. The manufacture and transportation of long bars are difficult, which limits the use of full length reinforced bars. The method used to join the reinforcement bars, so that the force is transferred effectively from one rebar to the other rebar is called as rebar mechanical splicing. The integrity of the concrete structure is dependent on the proper mechanical splicing of the reinforcement bars.

2020-04-23

Live Chat

Live Chat