ADTO News

-

Four Types of Scissor Lifts

As mentioned before, scissor lifts can be divided into three different types: Hydraulic scissor lifts are powered by hydraulic oil. Electrical or diesel scissor lifts are powered by electricity or diesel. Pneumatic scissor lifts are powered by air pressure.

2020-05-26 -

Do You Know How Aluminum Foil is Produced?

The thinner aluminum sheet plate is aluminum foil .When aluminum alloy is passed between rolls under pressure, it becomes thinner and longer in the direction in which it is moving. This simple process is the basis for producing aluminum plate, aluminum sheet, and aluminum foil. The production of sheet or aluminum foil usually starts out the same way as plate but the slab is further rolled through a continuous mill to reduce the thickness and wound into a coil at the end of the line. These coils are subsequently cold-rolled, from one to several passes at cold rolling mills.

2020-05-22 -

Why Should We Choose ADTO Container House?

Container house is a form of the house using steel intermodal containers as structural elements. The use of containers as a building material has grown in popularity over the past several years due to their inherent strength, wide availability, and relatively low expense. Homes have also been built with containers because they are seen as more eco-friendly than traditional building materials such as brick and cement.

2020-05-22 -

Do You Know the Characteristics of Aluminum Foil?

Aluminum foil, commonly known as tin foil, tin foil is a kind of flattened metal aluminum manufacturing tool, mainly used for cooking in the kitchen, carrying food, or to make some simple cleaning materials. Most of the aluminum foil is glossy and the other side is gray. Food can be wrapped in aluminum foil on both sides. It is usually recommended to wrap food in bright bread to improve heat conduction. Because of its soft texture, good ductility, and silver-white luster, aluminum foil can also be printed if the calendered sheet is mounted on offset aluminum foil paper with sodium silicate and other materials.

2020-05-21 -

Why Should You Choose ADTO Slope Prefab House?

Slope prefab house is widely used as temporary buildings in the construction site. The reason why we choose ADTO slope prefab house is listed as follows:

2020-05-21 -

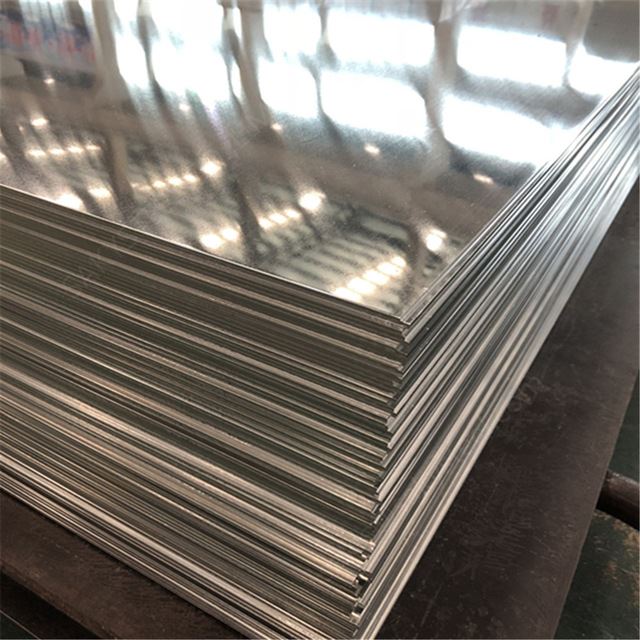

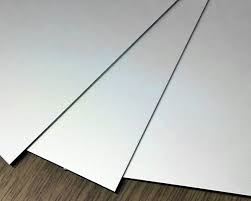

What’s the Difference Between Aluminum Sheet And Aluminum Plate?

With an outstanding strength-to-weight ratio and natural corrosion resistance, aluminum sheet metal is popular for a broad range of applications. Aluminum sheets and plates are used in everything from aerospace and aircraft manufacturing to beverage packaging, cryogenic storage applications to siding, gutters, and roofing for homes.

2020-05-20 -

Do You Know What is Tubular Scaffolding?

Tubular scaffolding is a time and labor-intensive system, but it offers unlimited versatility. It allows for connecting horizontal tubes to the vertical tubes at any interval, as long as there is no restriction due to engineering rules and regulations. Right angle clamps connect horizontal tubes to the vertical tubes. Swivel clamps are used to attach diagonal tubes.

2020-05-19 -

How to Pick Right Type of Scaffolding for Use?

A scaffold also identified as staging is referred to as a temporary configuration, which acts as a support for the people and materials for the renovation/construction of buildings. Since ancient times, these structures have been used in many places world over and gained an enormous amount of importance. You’ll find numerous types of scaffolding like wooden structures made from bamboo, modular structures, metal pipes, and preassembled structures. Thus, it is imperative to buy or rent the right type of scaffold for your home or office; however, it is more important to get the right type of scaffold for use.

2020-05-18 -

Do you Know Different Types of Scaffolding?

Let’s go over the different types of scaffolding. These days, there are diverse types of scaffolding available in the market; however, the most widely used scaffold types are listed out here:

2020-05-15 -

Do You Know the Advantages of Steel Scaffolding?

Steel Scaffolding is manufactured in such a way that it can be reused. To make work easy and safe, it also comes with safety lines, decking along with other supplies. In sites wherein the workers need to be working with electricity, there is a provision for insulation so as to reduce the danger of any sort that can occur due to electric shock. Workers should examine all the loose pieces constantly when working with steel scaffolding.

2020-05-14 -

Some Things You Should Remember When Buying Scaffolding

When it comes to buying scaffolding, there are many tips you should bear in mind. Here are some things you should remember when you purchase scaffolding.

2020-05-13 -

Painted Scaffolding VS Galvanized Scaffolding

Scaffolding is a construction tool used to support construction personnel working at height. As we can see that there are some scaffolding systems are painted while other scaffolding systems are galvanized. But why are some scaffolding system painted while others are galvanized?

2020-05-12 -

Do You Know The Major Advantages of Kwikstage scaffolding?

Scaffolding is used to ensure that the workers working at heights from falling down or tumbling. Over the decades, kwikstage scaffolding has been proved to be the most efficient form of scaffolding. It could be quite hard for the construction personnel to manage their work without kwikstage scaffolding. Kwikstage scaffolding is revolutionary and cost-efficient. It includes the scaffolding tube and other fitting methods. It is a brilliant alternative to conventional scaffolding. Due to its advantages, kwikstage scaffolding is being used all over the world.

2020-05-11 -

How to Do Works on Scaffolding Erections, Adjustment & Dismantling?

Several instructions for completing scaffolding erection, adjustment, dismantling works safely:

2020-05-09 -

How to Do Scaffolding Erection?

Scaffolding erection is risky construction activity. To ensure the safety of construction personnel when doing scaffolding erection, there are the following points you need to take into consideration.

2020-05-08

Live Chat

Live Chat