ADTO News

-

What is Scaffolding Ladder Beam and How Does It Work?

A scaffolding ladder beam, resembling a ladder, composed of a pair of tubular members connected by struts. There are two kinds of scaffolding ladder beam manufactured by ADTO GROUP: galvanized steel ladder beam and aluminum ladder beam. The steel ladder beam is manufactured with high strength steel. Then through the process of zinc-coating or hot-dipped galvanization, the steel ladder beam will have the best performance in anti-rust and corrosion-resistant. But with a long time using, the zinc-coat will be worn out, the steel under the zinc-coating may be rusted and corroded without its protection.

2020-11-13 -

What is Ringlock Scaffolding and Why Ringlock Scaffolding is So Hot?

When it comes to buying a reliable and adaptable scaffolding system, ringlock scaffolding has become a hot choice nowadays. Ringlock scaffolding, like other types of scaffolding systems, such as Cuplock scaffolding and Kwikstage scaffolding, is a kind of easy erecting scaffolding. Ringlock scaffolding consists of prefabricated components, each component designed specifically for its intended purpose. Scaffold contractors and construction companies often opt for ringlock scaffolding system, mainly due to the speed of installation and ease of adaptation all types can provide.

2020-11-02 -

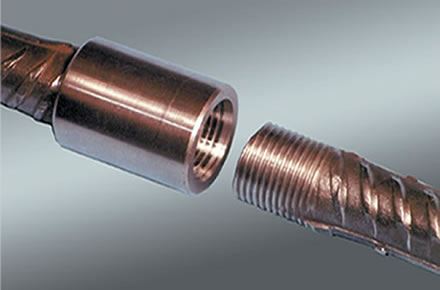

ADTO Mall: Leading Rebar Mechanical Coupler Supplier

In recent years, the demand for a more efficient rebar splicing system is increasing because of the rising requirements on construction complexities and design requirements. The use of rebar couplers can simplify the design and reinforced concrete construction. Using ADTO rebar mechanical splicing can also reduce the amount of rebar required.

2020-10-20 -

Do You Know ADTO Rebar Connection System?

ADTO Rebar Connection System is a high quality, economical connection system of reinforcement. ADTO Rebar Connection System is a simple, efficient method for connecting reinforcement steel, which eliminates the disadvantages of the traditional procedure of lapped joints. The lapped joints system may provide long-term consumption, greater rebar congestion, and unsafe usage in seismic zones.

2020-10-16 -

Difference Between Seamless Steel Pipe And Welded Steel Pipe

There are two types of steel pipe/tube. One type is a seamless steel pipe, and another type is the SAW steel pipe that has a single welded seam along its length. While SAW steel pipe can be divided into LSAW steel pipe and SSAW steel pipe. Both seamless steel pipe and seam steel pipe have different uses. The difference in the basic manufacturing method is obvious from the names. A seamless steel tube is extruded and drawn from a billet while the SAW tube is produced from a strip that is roll formed and welded to produce a tube.

2020-10-12 -

Application of Plastic Formwork

The technology of cast-in-situ ribbed slab with plastic formwork has been used in the National Library and other projects. Mature complete construction technology has been established. Plastic formwork products have been able to mass production, with a complete production process and all necessary means of production.Plastic formwork can be used in large space public buildings, industrial workshop construction. The cast-in-place ribbed floor slab with plastic formwork can save steel and concrete compared with general conventional formwork. Plastic formwork use no wood, reduce the cost by 1/3, and shorten the construction period.

2020-09-29 -

Design Technique & Advantages of Plastic Formwork

The steel frame of plastic formwork can be welded with 80×80×8 Angle steel as side rib, no. 8 channel steel as vertical rib and No. 5 channel steel as horizontal rib. The plastic sheet is set in the steel frame and connected by bolt or riveting. Pin plate, U-shaped card or special fixture are used to connect the steel frame with the steel frame. The frame size of plastic formwork can be designed as 1200mm×3000mm, 1200mm×2400mm, 600mm×3000mm, 600mm×2400mm, 600mm×1800mm, etc. Besides, it is also equipped with adjusting formwork, negative angle die, positive angle die, diagonal braces, overlays, tension bolts and formwork fixture, etc.

2020-09-27 -

Major Advantages of Plastic Formwork

1) Smooth surface, high strength, saving labor, and material cost, can meet the requirements of fair-faced concrete formwork. After demolding, there is no need to clean the formwork surface, thus saving labor forces. The flatness of the formwork can be controlled within 0.3mm. The thickness of the formwork can be even and controlled with the tolerance of 0.3mm, saving 2/3 of the nails compared with the plywood formwork.

2020-09-22 -

Comparison of Steel Formwork And Plastic Formwork

Plastic formwork is a product with characteristics of energy-saving and environmental friendly. It is one of the direction of the development of construction industry in the future. Plastic formwork is made of fiber high-strength plastic. When the raw materials are in the molten state, the plastic formwork is single molding shaped with shooting technique. Plastic formwork has advantages of simple craft, light weight, low cost, and circular use. It has the same mechanical properties as the steel formwork. Plastic formwork has a broad development prospect as it can replace the steel formwork in the construction industry for most purposes. Below we will make a comparison between plastic formwork and steel formwork as shows below.

2020-09-17 -

Ringlock Scaffolding In 2020

Ringlock scaffolding is a new type of scaffolding introduced from Europe in the 1980s. It is an upgraded scaffolding products of cuplock scaffolding. The standard with spigot is made from Q345 material steel pipe with hot dip galvanized surface treatment. The spigot on the standard is designed with 8 holes. These eight holes are used to connect traverses and diagonal braces.

2020-09-10 -

Three Key points of Scaffolding Acceptance

When will the scaffolding acceptance be conducted? (1)After completion of foundation and before the erection of scaffolding; (2)After every setting a height of 10-13 meters; (3)After reaching the design height; (4)Before the load is applied to the operating layer; (5)After force six-strong winds and heavy rain; After freezing in cold areas; (6)Be out of use for more than a month.

2020-09-03 -

Difference Between Hot Rolled and Cold Rolled Steel Coil

There are many customers often ask us a question about the differences between hot rolled steel coil and cold rolled steel coil. Today we will have a discussion about that. The hot rolled steel and the cold-rolled steel coil, they only have one difference in the word. So what’s the difference between hot rolled steel coil and cold rolled steel coil? There are some primary differences between these two types of steel coil. These differences are related to the ways they are manufactured or something about the manufacturing technique. The difference between hot rolled steel coil and cold rolled steel coil is not about the product specification or grade.

2020-08-25 -

Points of Attention for Scaffolding

As the building construction volume continues to increase, the huge scaffolding group is likely to exist several kinds of safety hazards at the same time, a lot of accident signs, are caused by some reinforcement measures are not in place. So what are some of the issues that need to be addressed?

2020-08-21 -

How to Distinguish the Omen of the Scaffolding Collapse?

Scaffolding is an essential facility in construction projects. While the scaffolding collapse and falling accident happened frequently in the construction industry in recent years. There are many reasons that cause scaffolding collapse and falling accidents, such as nonstandard scaffold erection, scaffold loading overweight during the construction work, arbitrary removal of the pull or stress bar, etc. Therefore, it is very important to strengthen the safety of scaffolding construction management. Then how can we distinguish the omen of the scaffolding collapse? There are three kinds of scaffolding collapse.

2020-08-18 -

Types of Formwork Used in Concrete Construction

Concrete is one of the most popular building materials as it’s safe, durable, sustainable, and economical. Formwork is an essential material used in concrete construction. Formworks are temporary or permanent molds that cannot be removed until the concrete is shaped into the designed structure.

2020-08-13

Live Chat

Live Chat