ADTO News

What’s the Difference between Octagonal and Ringlock Scaffolding?

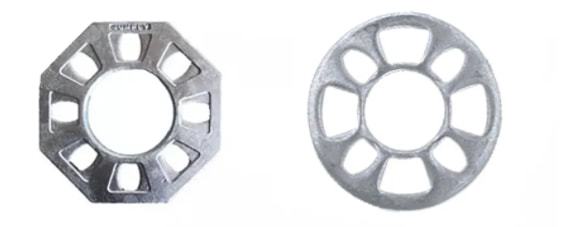

Most of the socket-type buckle-type scaffolding connecting plates are mainly ringlock plates, and there is another kind of connecting plate that is octagonal.

Why the octagonal plate is better than ringlock plate? Today, I will show you the advantages of octagonal scaffolding.

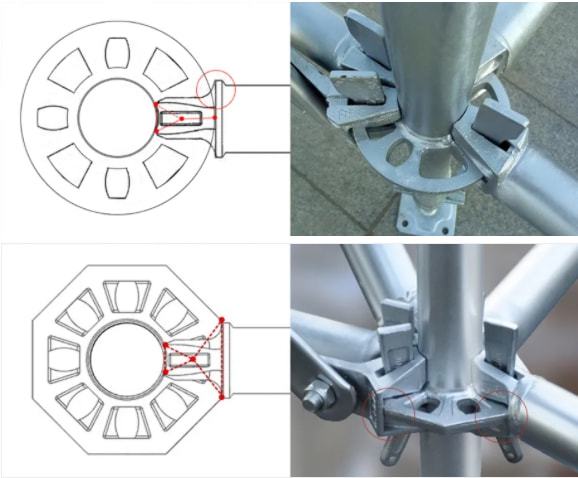

The biggest feature of the octagonal plate is that the node has strong torsional resistance and good stability.

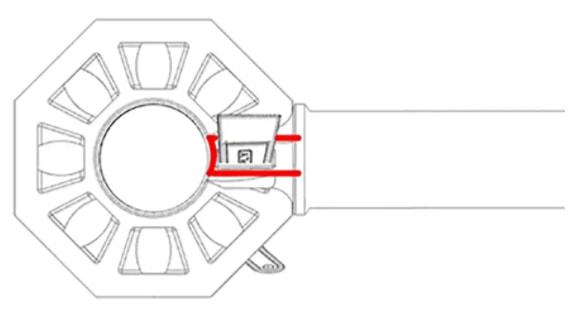

When the crossbar and the vertical bar are connected, the U-shaped groove of the buckled joint is in contact with the edge of the connecting plate. The octagonal plate is surface contact plus a pin, forming two groups of stable and reliable triangular force systems, and the overall torsional rigidity is strong.

The U-shaped groove of the horizontal rod buckle joint is stuck to the upper and lower limit after the octagonal plate, and will not move up and down

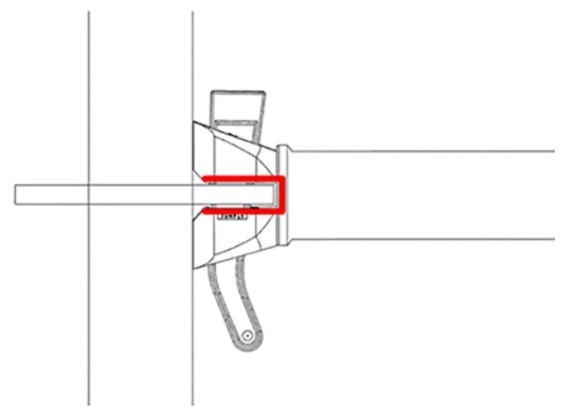

The arc design at the top of the horizontal rod buckle joint can be in close contact with the surface of the steel pipe of the vertical rod. With the addition of the latch, it can limit the left and right positions and will not move left and right.

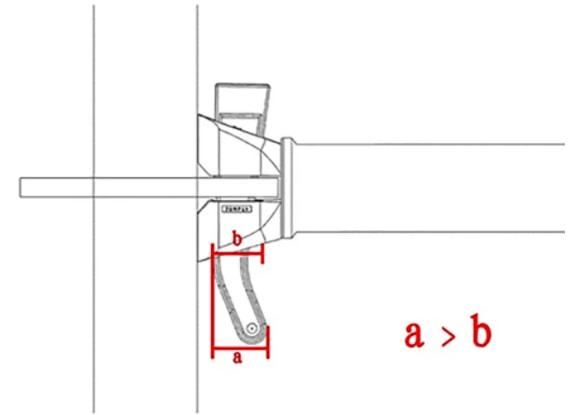

The bolt is designed with a self-locking angle, and the self-locking ability is strong after the bolt is tightened; the bottom of the bolt is designed as a hook, and the total width of the hook is greater than the length of the corresponding hole of the crossbar buckle joint, even if the bolt is not tightened, the bolt will not jump out.

The difference between octagonal disc type steel tube scaffold and disc type steel tube scaffold.

Aspects | Octagonal Disc Type Steel Pipe Scaffolding | Ringlock Disc type steel tube scaffolding |

Nodal Torque Capability | The U-shaped groove of the crossbar buckle joint is in surface contact with the edge of the octagonal plate on the vertical bar | The U-shaped groove of the horizontal rod buckle joint forms a point in contact with the disc on the vertical rod |

The hole size of the octagonal plate is the same, and the connection between the pin and the plate is firm | The hole size of the ringlock plate is different, and the horizontal rod can be rotated at a small angle | |

Anti-tripping pin | The latch is designed as a hook, and the total width of the hook is greater than the length of the corresponding hole of the crossbar and the joint | Straight pin |

Erecting | The overall structure of the welding sleeve at the top of the pole is consistent | A connecting rod is set at the top of the pole, and the top connecting rod may be removed during use |

Loss | No scattered and small components, less material loss, and less loss | The pole connecting rod and the starting seat are small components |

The axes of the vertical poles, the horizontal poles, and the inclined poles of the octagonal disc type scaffold meet at one point, which is a two-force pole. The force transmission path is simple, clear, and reasonable, the structure is stable and reliable, and the overall bearing capacity is high; , Reasonable materials, make the best use of materials, reduce the amount of steel used, save materials and save energy.

Standard: Every 0.5m on the pole is welded with an octagonal connection plate that can be buckled with 8 direction buckle joints, and one end of the pole is welded with a connecting sleeve to fix the pole.

Crossbar: The two ends are welded with buckle joints, and the rod is buckled with the octagonal plate of the vertical pole.

Diagonal Brace: The two ends are provided with buckle joints, and the rods are buckled with the connecting plate on the vertical pole to keep the structure of the frame body stable, and its length is determined by the length of the vertical pole and the horizontal pole.

Adjustable Base: Mounted on a height-adjustable base on the lower end of the pole

Adjustable bracket: Height-adjustable top bracket mounted on top of the pole

Live Chat

Live Chat