ADTO News

What Are the Advantages of Ringlock Scaffolding When Compared with Traditional Kinds

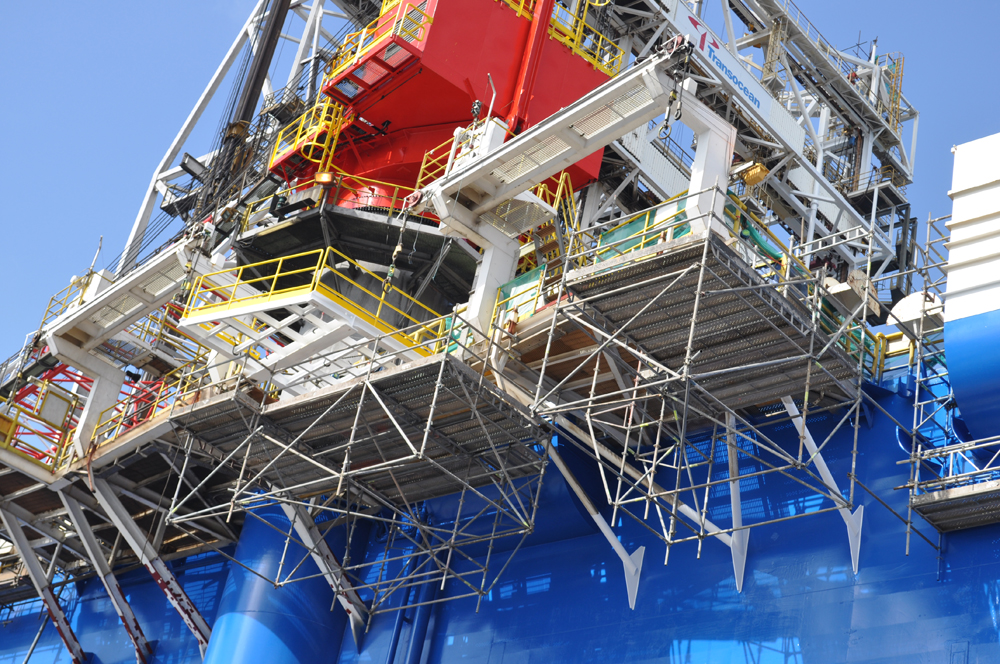

1. Locked scaffolding erection more secure and efficient

The ringlock scaffolding pole is made of Q345 grade steel forging, which has higher strength than the original Q235 steel, and the bearing capacity of single pole is more than 20 tons. Unique design of the button, so that the rod between the multi-directional solid connection to meet the scaffolding erected a variety of connection requirements.

And ringlock scaffolding supporting the use of steel plank is more than the traditional bamboo plank with unparalleled safety performance. And tailored scaffolding for the treadmill is for the operating staff in case of emergency provides an emergency evacuation of the channel, the maximum protection of the lives of workers safety.

Erection of the efficient is self-evident. Because all the connections are made by the latch, the operator as long as a hammer can complete the solid connection between the bars. Second, the bobbin scaffolding can better cost savings and higher efficiency

Although the panel scaffolding system from the one-time purchase cost point of view, than the ordinary steel fastener scaffold high, but in the long run, the actual annual cost of the average cost is much lower. Specific analysis from the following two aspects.

The number of bars. As the pole with Q345 grade steel, higher strength, the spacing between the rods can be larger, up to 2 meters. This reduces the number of poles, so as to achieve the purpose of reducing costs.

2. use time. As the surface of the rod are hot dip galvanized treatment, which has a longer durability, life of up to 15 years or more, do not need regular maintenance, every 3 to 5 years to maintain once. The general life of steel pipe scaffolding is only about 5-8 years, and must be 1-2 times a year maintenance. Obviously, the maintenance cost of traditional scaffolding is much more than the maintenance cost of the bobbin scaffolding.

Live Chat

Live Chat