ADTO News

-

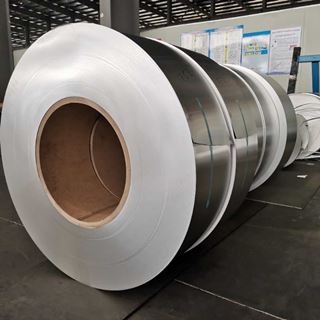

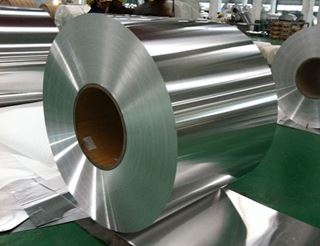

Aluminum Coils Manufacturer in China

Aluminum coil sheets are easier to store and transport than many stacked individual sheets. Aluminum coils are supplied to manufacturing operations, metal fabricators, and other metalworking operations by aluminum suppliers. When a coil of aluminum arrives at a metalworking facility, it can be subject to all manner of processing. Coiled aluminum can be stamped, etched, cut, welded, bent, and fastened to other metal products.

2022-06-30 -

What is Aluminum Coil?

An aluminum coil is a metal product that is subjected to flying shear after being rolled by a casting and rolling mill and processed by drawing and bending.

2022-06-30 -

What is Octagonlock Scaffolding?

Octagonlock scaffolding system is a new kind of ringlock type scaffolding. The spigots on the standard have 8 straight holes, which perfectly fit the ledger and diagonal heads, making the system more stable. Octagonlock scaffolding is the prototype of a scaffolding system. It is now mainly and widely used in both domestic and abroad markets.

2022-06-29 -

What Are the Differences Between Sunshade Nets And Shade Netting?

Aluminum foil shading net is generally made of pure aluminum foil strips and transparent polyester film strips. It is probably better than the shading net of the same density, but it actually reduces the temperature caused by light radiation. So what are the differences between shade nets and shade nets?

2022-06-29 -

What Types of Shade Nets Are There?

Sunshading net, also known as shading netting, is a special protective covering material used for agriculture, fishing, animal husbandry, wind protection, soil covering, etc. After covering in summer, it plays a role in blocking light, rain, moisturizing, and cooling. So what types of shade nets are there?

2022-06-27 -

Crafts of Plastic Templates

Roof plastic formwork support: the distance between the sub-corrugations is determined according to the thickness of the plate. Under normal construction conditions, the distance between the sub-corrugations (center distance) for floors less than 150 thick is 350 to 400 mm; Compared with the normal use of bamboo plywood formwork, the spacing of the secondary corrugations is increased by 50mm, and the flatness deviation of the concrete surface is smaller, which truly achieves the effect of fair-faced concrete.

2022-06-24 -

The Method of Eliminating the Fitting Gap of Rebar Thread Connection Sleeve

The steel bar connection sleeve is a mechanical connection in the steel bar connection method. It is suitable for the connection between large-diameter steel bars. It has the characteristics of energy-saving and is not limited by the composition and type of steel bars. It is widely used in construction. Do you know the method to eliminate the thread fit-gap of the steel connection sleeve?

2022-06-22 -

The Seven Principles of Straight Threaded Steel Bar Connection Sleeve Connection

1. The straight-threaded steel bar connection sleeve joint should be set at the place where the force is less, and fewer joints should be set on the same steel bar. 2. The tie rods (axial tension and small eccentric tension members) of the wooden frame and the arch shall not be bound and lap joints. 3. When the diameter of the tensile steel bar is greater than 28mm and the diameter of the compression steel bar is greater than 32mm, it is not appropriate to use the lashing lap joint;

2022-06-16 -

The Traditional Rebar Connection Method Will Be Replaced by the Rebar Connection Sleeve

The traditional lap joint, welding, and other connection methods are replaced by steel connecting sleeves so that they can meet the requirements of the rapid development of the construction industry in terms of connection quality, efficiency, and operability, and further promote the technological innovation of the entire industry.

2022-06-15 -

Importance and Requirements of Steel Connecting Sleeve

The design basis of the steel bar connection sleeve has a high dimensional tolerance level, IT4 level, and the surface roughness is 0.8. These technical conditions are to ensure the matching accuracy of the straight thread connection sleeve and the bearing and the smooth movement.

2022-05-31 -

Classification and Advantages of Steel Rebar Sleeves

With the rapid development of the construction industry, traditional steel bar connection methods can no longer meet the needs in terms of connection quality, connection efficiency, and operability. The continuous updating of steel bar connection sleeve technology has driven the progress of the entire construction industry. Today, I will introduce the classification and advantages of steel threaded sleeves in detail.

2022-05-31 -

How to Identify Whether the Steel Straight Thread Sleeve is Qualified?

Steel bar straight threaded sleeves play the role of connecting steel bars in construction, and they are matched with different types of steel bars, so it is very important to select a batch of steel bar sleeves that meet the needs of the project, so I will popularize the identification of steel bar straight-A method for qualifying threaded sleeves.

2022-05-30 -

Installation Steps of Steel Bar Straight Thread Sleeve

A Steel bar straight thread sleeve is a kind of steel bar processing machine that has been widely used in the construction industry in recent years. During the use process, we must pay attention to the installation matters, which can avoid some technical problems. Does not affect the progress of the project.

2022-05-27 -

Differences between the Connection of Straight Thread Sleeve and Cold Extrusion Sleeve

The connection of the steel bar straight thread sleeve is to peel off a part of the longitudinal and transverse ribs at the end of the steel bar to be connected by cutting with a thread rolling machine, and then directly roll it into an ordinary straight thread and connect it with a straight thread sleeve. The technology is efficient, convenient, fast, saves energy and reduces consumption, improves efficiency, and the connection quality is stable and reliable.

2022-05-26 -

What is the Difference between Cold Rolled Sheets And Hot Rolled Sheets?

The main differences between the cold-rolled sheets and hot-rolled sheets are as follows:

2022-05-25

Live Chat

Live Chat