ADTO News

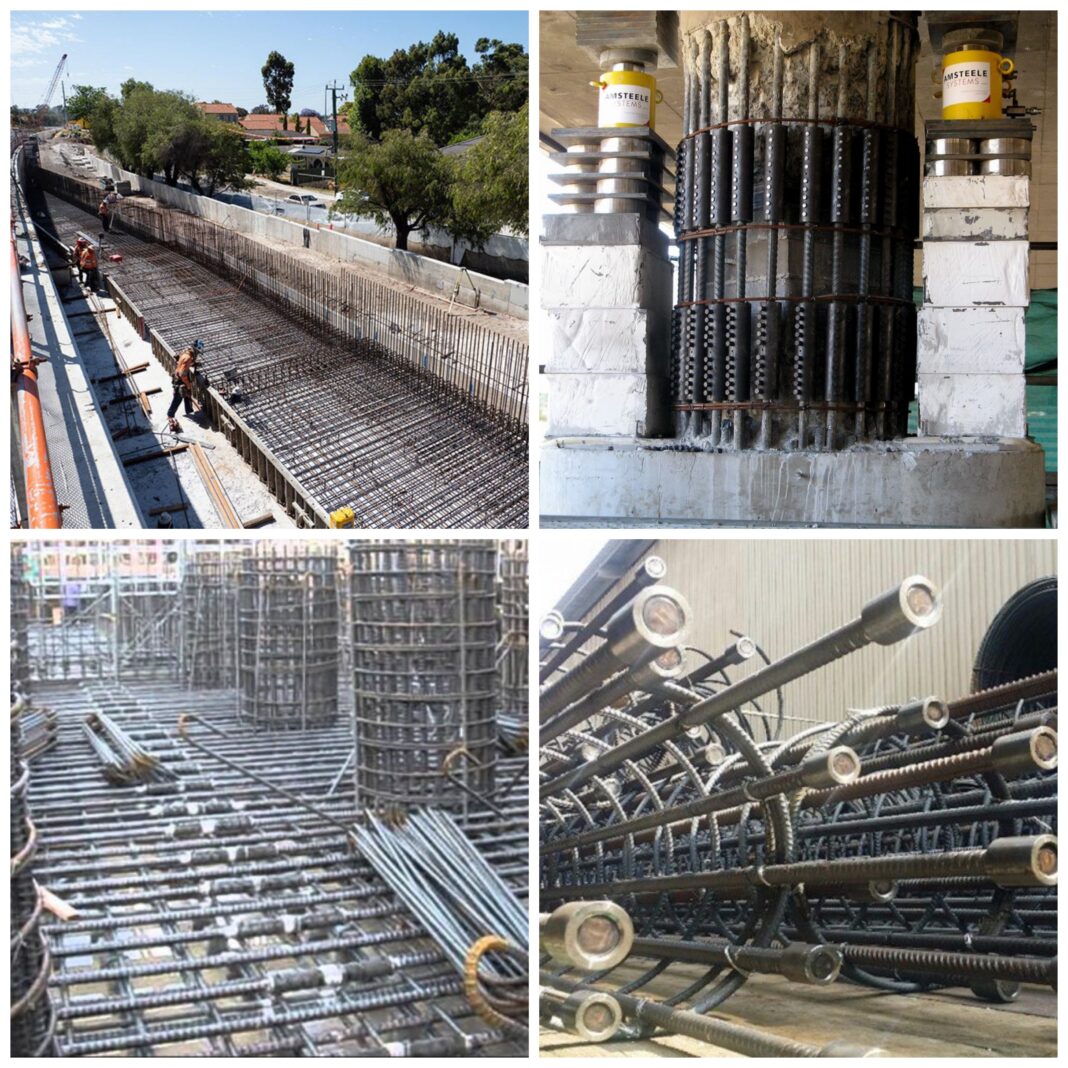

The Mechanical Splices For Concrete Rebar

Mechanical splices are used to establish a mechanical connection between two pieces of reinforcing steel in concrete construction for joining reinforcing bars. The mechanical splicing system aligns and secures the joined rebar ends in an in-line connection suitable to meet appropriate splice requirements.

Mechanical splices are being adopted in project sites due to their flexibility of use in congested reinforcement places at construction joints. These connections are also more reliable than the lap systems because they do not depend on the concrete for load transfer. The splices also allow structural designers to achieve an ideal balance of steel and concrete by eliminating the additional rebar lap zone by meeting building code requirements in many areas. In seismic prone zones, these splices provide structural engineers the ability to design and build concrete structures that meet or exceed today’s stringent construction codes and federal regulations regarding seismic frame construction.

#1 Advantages of Mechanical Splices for Concrete Rebar

a. Maintains load path continuity of the reinforcement, independent of the condition or existence of the concrete.

b. Does not rely on the concrete for load transfer and therefore maintains structural integrity.

c. As mechanical splices do not overlap, less rebar is used, reducing some of the material costs.

d. It reduces the rebar congestion by decreasing the rebar in the lap zone and simplifying bar placement

e. Using mechanical splices allows the option of larger diameter rebar in a smaller column while minimizing congestion

f. Decrease the possibility of pockets and voids in the concrete

g. Provides higher performance than typical design lengths for lap splices

h. Allows the structural designers to achieve an ideal balance of steel and concrete by eliminating the additional rebar in the lap zone

i. Eliminates lap calculations

j. Eliminate the cost of breaking away massive amounts of concrete.

k. Faster installation

l. Reduces crane use

m. Limits drilling of formwork

#2 Different types of mechanical splices

1.Coupler for Thread-Deformed Bar

2.Upset Straight Thread Coupler

3.Non- upset thread Coupler

4.Cold-Swaged Threaded Coupler

5. Taper-Threaded Coupler

6.Straight Threaded Coupler with Upset Rebar Ends

7.Grout-Filled Coupling Sleeve

8.Combo Grout-Filled/Threaded Sleeve

9.Metal-filled coupling Sleeve

10.Cold-Swaged Coupling Sleeve

11.Shear Screw Coupling Sleeve

12.Coupling Sleeve with Double Wedge

13.Coupling Sleeve with Shear Bolt/Wedge

14.Dowel Bar Mechanical Splice

15.Compression-only Mechanical Splice

Applications of mechanical splices

A. Tunnels

B. Bridges

C. Commercial buildings

D. High-rise buildings

E. Subway

F. Airports and many more

G. Conclusion

Working with small diameter reinforcing bars may require the use of larger column dimensions to accommodate a greater quantity of bars. Using mechanical splices allows the structural engineers the option of using larger diameter rebars in the smaller column while minimizing congestion. All the advantages are discussed above and there are many types of mechanical splices available in the market, choose the right one as per project needs. Go for experienced manufacturers ADTOMall to find high-quality rebar splices.

Live Chat

Live Chat