ADTO News

-

Why Ladder Ratings is Important?

We should pay more importance to duty ratings when we buy ladders. Ladder grades assign maximum weight capacities for each ladder.

2022-08-11 -

Safety Tips For Ladder Use

Regardless of the ladder types and grades you use, there are several best practices and safety tips to keep in mind. These tips cover best practices from ladder selection, inspection, set-up, and use.

2022-08-09 -

What Are Ladders Made of?

In addition to ladder types, different ladder materials present unique pros and cons. A majority of ladders are made from metal, wood, or fiberglass. The material that works best for you will depend on your budget, project requirements, and transportation requirements.

2022-08-05 -

What is H Frame Scaffolding?

H frame scaffolding system is a platform used in plastering works on interior walls and facades in construction. Frame scaffolding systems are also used for facade painting, insulation, facade cladding, and building and repair of ships.

2022-08-04 -

Types of Shoring Props

Shoring props can be generally divided into the following two types.

2022-07-29 -

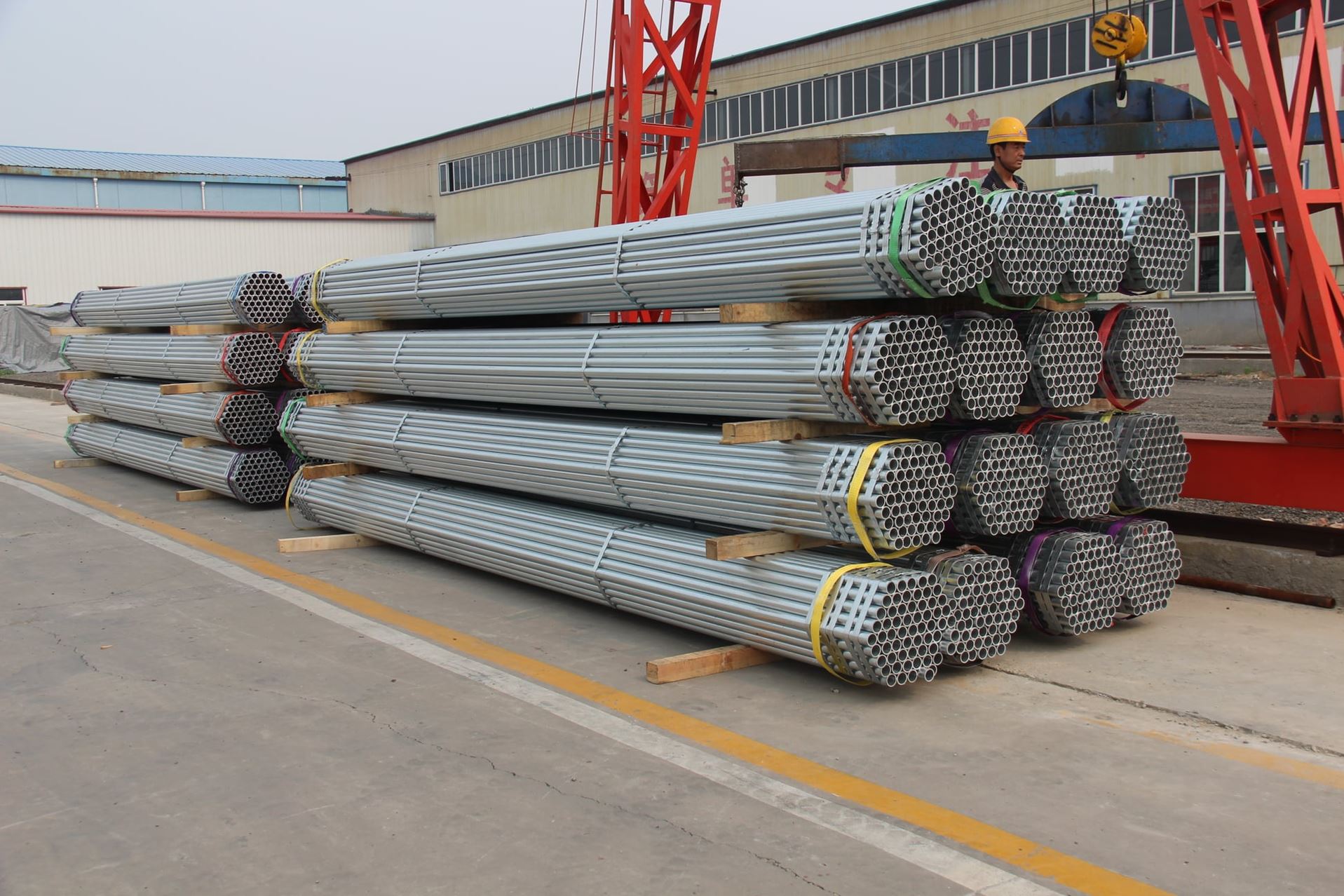

Difference between Seamless Steel Pipe and Galvanized Steel Pipe

As an important part of steel products, steel pipes are divided into two categories: welded steel pipes (plates, strip billets), and seamless steel pipes (round billets) according to their different manufacturing processes and shapes of billets. As for galvanized and seamless steel pipes, it cannot be said that there is any difference in the material. Their classification standards themselves are different. Galvanized pipe is a surface treatment process.

2022-07-29 -

How to Select Best-quality Scaffolding Acrow Steel Props?

The acrow steel prop is a load-bearing component that can support the platform to a specified height. Workers can choose different acrow steel props according to the height of the construction. ADTOMall, as a leading professional scaffolding steel props manufacturer, would like to introduce how to select the best quality scaffolding steel props.

2022-07-29 -

Scaffolding in Construction

The scaffold used in building construction is a temporary platform used to elevate and support workers and materials during the construction. Workers can stand on the scaffolding in building construction to repair or clean supporting structures or machines. A scaffolding system consists of one or more planks of convenient size and length, with various methods of support, depending on the form and use.

2022-07-28 -

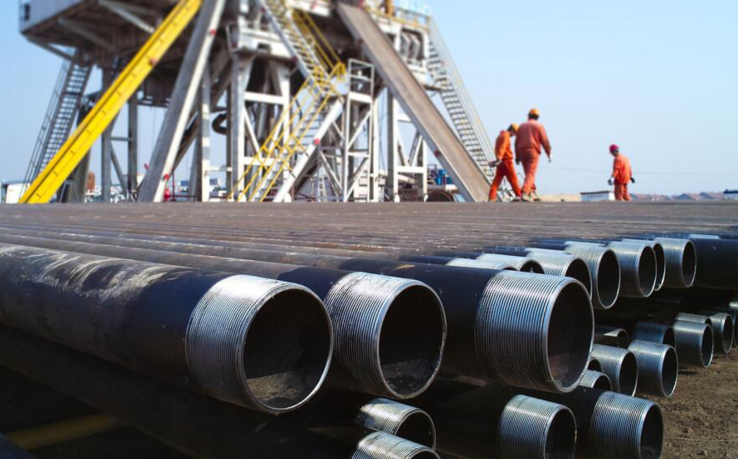

What are the Different Types of OCTG Pipe?

There are four types of OCTG steel pipe listed as follows.

2022-07-27 -

What is OCTG?

OCTG is the acronym for Oil Country Tubular Goods. OCTG is the tube and pipe which is used in the production of oil and gas. OCTG is a wide range of steel tubular products which are used in the exploration, development, and production, of oil and gas, particularly in the drilling process.

2022-07-27 -

Factors Affecting the Quality of Casing String Threaded Connection

Oil casing pipe is also called special oil pipe, which is mainly used for the drilling of oil and gas wells and the transportation of oil and gas. It includes oil drilling pipes, oil casings, and oil sucking pipes.

2022-07-26 -

Steel Pipe Standard: ASTM A53 GR.A GR.B

ASTM A53 American standard (non-plated and hot-dip galvanized welded and seamless nominal steel pipe), ASTM A53 is the executive standard for steel pipes, and Gr.B is the steel grade (level) of steel pipes According to the standard name: Both welded pipe and seamless pipe can be produced, depending on customer requirements.

2022-07-20 -

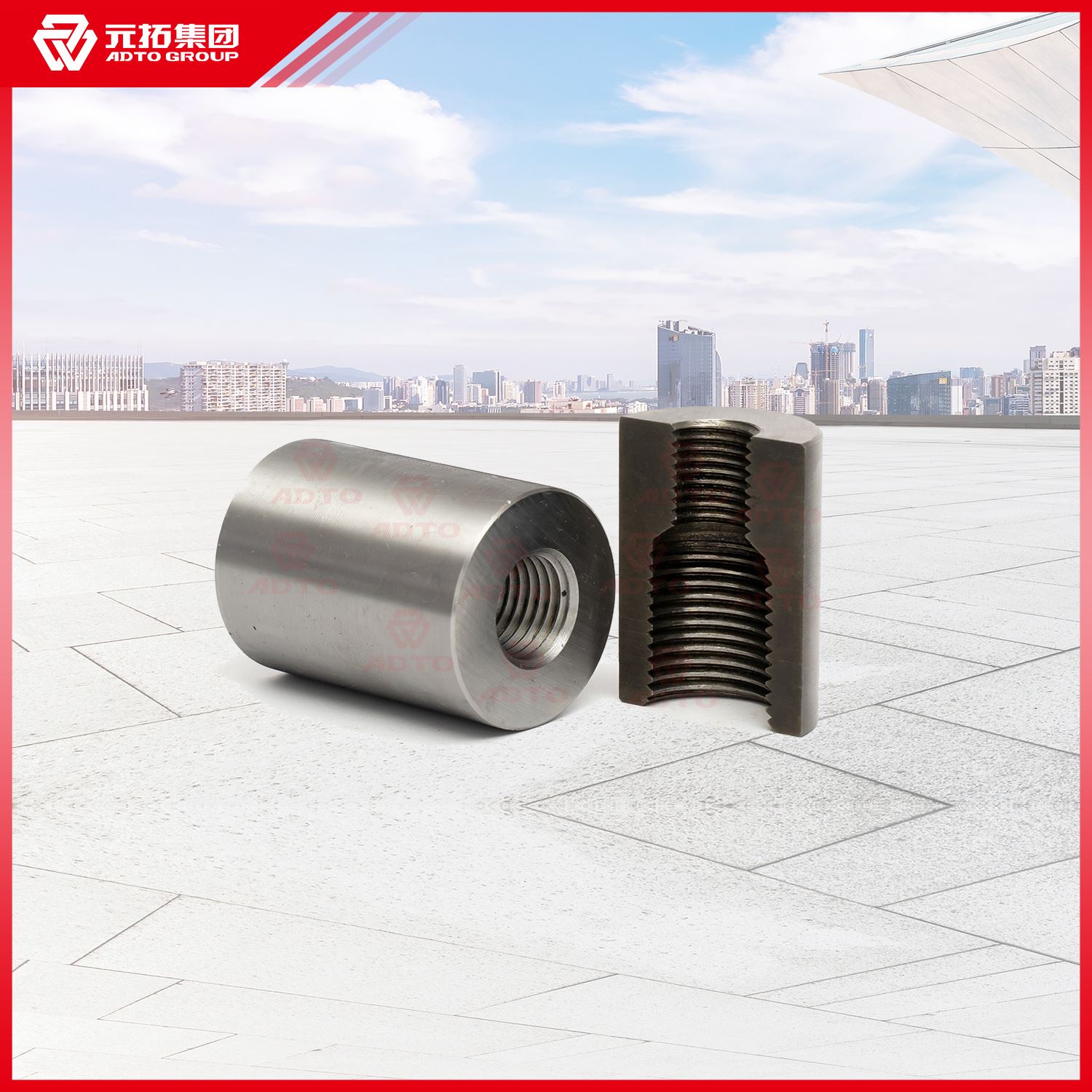

Installation Steps of Straight Thread Rebar Coupler

We must pay attention to the installation when using a straight thread rebar coupler to avoid technical problems, which may affect the quality of the product.

2022-07-19 -

Precautions of Safety net

Safety nets are essential protective equipment for workers working at heights. The relevant regulations must be strictly observed during its use.

2022-07-13 -

Aluminium Coil: An Earth-Friendly Industrial Material

Whether a project calls for aluminium foil or aluminium sheet, the aluminium coil is behind the manufacturing process. An aluminium coil is formed by taking one continuous strip of aluminium and coiling it into a roll.

2022-06-30

Live Chat

Live Chat