ADTO News

-

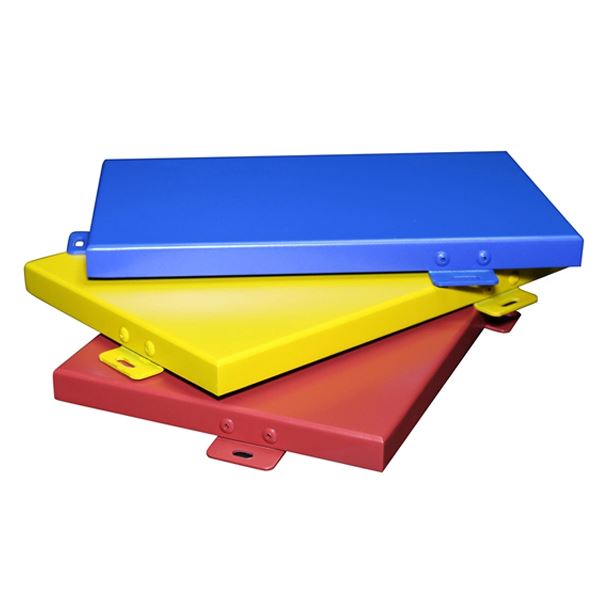

Features of Aluminium Venner

The aluminum veneer is made of high-grade aluminum alloy, and is processed by various processing techniques such as cutting, folding, bending, welding, reinforced, grinding, painting, etc. As a main choice for building cladding, aluminum veneer has a broad development space compared with exterior materials such as ceramic tile, glass, aluminum composite panel, honeycomb panel and marble.

2024-04-09 -

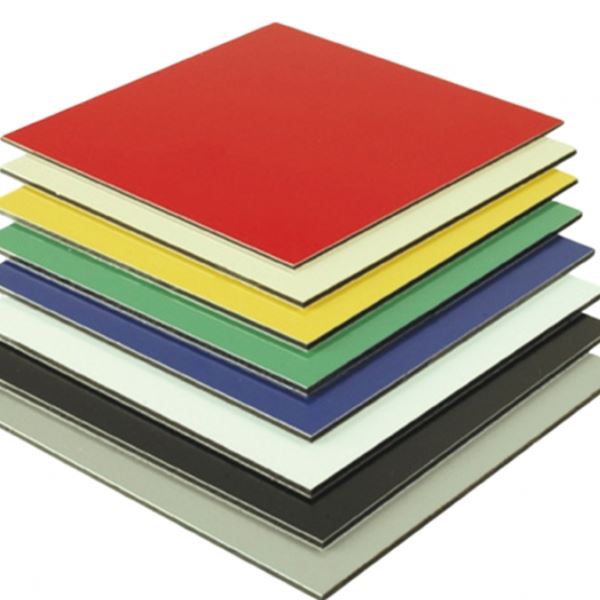

Differences Between Aluminum Composite Panel And Aluminum Veneers

Do you know the differences between aluminum composite panel and aluminum veneer? And how do we choose decorative material among aluminum veneer and aluminum composite panel? We will show you the difference in this passage.

2024-03-28 -

The Differences Between Cuplock Scaffolding and Kwikstage Scaffolding

Cuplock scaffolding and kwikstage scaffolding are two of the most popular types of scaffolding used in construction industry. But many people don’t understand the differences between cuplock and kwikstage. In this passage, we will help you to understand the key differences between cuplock scaffolding and kwikstage scaffolding.

2024-03-14 -

The Difference Between Aluminum Veneer and Aluminum Sheet

Aluminum is widely used in our human being world. There are many people cofused about the diffrence between aluminum veneer and aluminum sheet. In this article, we will make an introduction of these two different materials and help you understand the difference between them.

2024-03-14 -

Factors to Consider When Choosing Steel Pipe Flanges?

Steel pipe flanges play a crucial role in the oil and gas piping systems, connecting valves with other equipment. Steel pipe flanges are the second-most commonly used joining mechanism after welding. Using steel pipe flanges provides added flexibility, allowing easier assembly and disassembly of pipe systems. They provide easier access during cleaning, repairs, and inspection of the oil and gas pipes.

2024-03-07 -

What is Headed Rebar Copuler?

Headed rebar couplers are a simple and effective alternative to hooks and long development length.

2024-02-29 -

How to Choose Steel Pipe Flange Materials?

When purchasing steel pipe flanges, you must consider the flange material in addition to physical measurements and bolt hole alignment. The chemical composition and physical properties are important in determining whether a material will be appropriate for a given application. You can look to a combination of standards to guide your decision.

2024-02-21 -

ADTO Aluminum Formwork Project Jinxin·Haoyue Huafu Project Has Been Completed

At present, ADTO Aluminum Formwork has reached strategic cooperation with Fortune 500 companies such as Vanke, Country Garden, and China Construction. Aluminum alloy formwork has served over 1,000 projects in overseas markets such as Southeast Asia and the Middle East.

2024-01-25 -

Factors To Consider When Choosing China Scaffolding Supplier

Scaffolding is a suppoting system used for holding materials and workers. It is so important that we should choose a good scaffolding supplier to purchase safe scaffolding.

2024-01-18 -

ADTO Aluminum Formwork Project:the Philippines PASAY city Vista land Apartment

ADTO Aluminum Formwork has also successfully completed more than 2,000 townhouses and more than 10 resort hotel projects. The successful completion of these projects has laid a solid foundation for the development of ADTO in the Philippine market.

2024-01-18 -

ADTO Aluminum Formwork Project: Quezon City Manhattan Apartment

ADTO Aluminum Formwork entered the Philippine market in 2015, and has completed VISTA LAND, SHANG, SM, Chinese developers and other projects. It has completed more than 20 aluminum model super high-rise commercial, office, hotel and apartment projects, more than 2000 townhouses and more than 10 resort hotel projects.

2024-01-11 -

Benefits Of Choosing An Aluminum Formwork Supplier

When it comes to construction projects, the choice of formwork supplier plays a crucial role in ensuring efficiency and cost-effectiveness. Opting for an aluminum formwork supplier offers a multitude of benefits. Firstly, aluminum formwork is lightweight, making it easy to handle and transport, resulting in reduced labor and transportation costs. Additionally, its durability and longevity make it a wise investment, as it can be reused multiple times without compromising structural integrity.

2024-01-04 -

ADTO Aluminum Formwork Project Case: Philippine Project Case Tour: Makati City Shangri-La Hotel Apartment

ADTO Group entered the Philippine market in 2012. Its main products are tubular scaffolding systems, frame scaffolding systems, ringlock scaffolding systems and other related building materials products.

2023-12-26 -

ADTO Aluminum Formwork Project Case: Liuyang Creative Jinxiu Community Project

In this project, the aluminum form products and construction scale provided by ADTO Aluminum Form reached nearly 500,000 square meters. The aluminum alloy formwork project shows excellent concrete forming effects, including excellent flatness, verticality, formwork joints, and wall appearance. Whether it is walls, beams, columns or floor slabs, they all show good architectural shaping effects, and their appearance, verticality and horizontality have been highly recognized by the industry.

2023-12-21 -

ADTO Aluminum Formwork Project Case: Pinglu Canal Super Project

The application of ADTO aluminum formwork in the Pinglu Canal Super Project is not only a simple replacement of traditional wood formwork and plastic formwork construction, but also a comprehensive upgrade of modern construction technology.

2023-12-14

Live Chat

Live Chat