ADTO News

-

Why We Use Plastic Formwork?

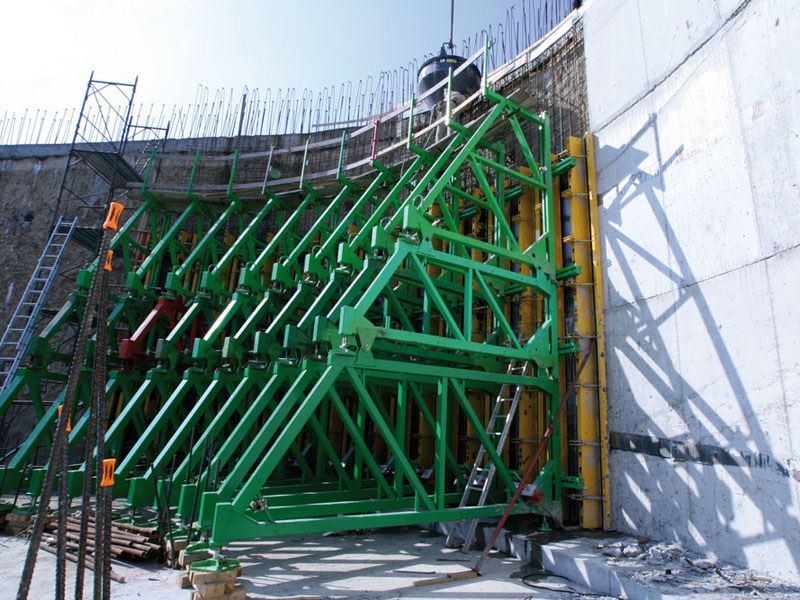

Everyone who saw the construction site will know that the concrete formwork was a temporary structure for concrete pouring, no matter it was plywood, or steel or plastic formwork, they will be dismantled after the concrete solid.

2019-08-30 -

Main Countries & Regions Manufacturing Plastic Formwork

The combined plastic modular formwork is a large-scale product which is assembled by the small formwork panels in cooperation with the assembly. The formwork can be flexibly assembled according to the specific construction requirements and has a wide range of applications. It has been widely used in Europe.

2019-08-30 -

Formwork System: Plastic Formwork Introduction

Plastic formwork mainly includes steel frame plastic formwork, engineering plastic large formwork, GMT building formwork, hollow plastic formwork, foam insulation plastic formwork, plastic modular formwork, etc., which can be widely used in walls, floors, columns, etc. In addition, there are also shaped plastic formwork processed into various shapes and surface patterns. The products are rich in finishes and various shapes. The formed concrete has a unique shape and surface texture.

2019-08-30 -

The Six Advantages of Plastic Modular Formwork

Due to the rapid development of urban construction, the concept of green and environmental protection has been deeply rooted in the hearts of the people. The rapid development of available resources in recent years has reached a culmination. How to save resources from many aspects has become a hot topic at the moment.

2019-08-30 -

When Choosing a Concrete Formwork, What Do We Need to Pay Attention to?

During the construction process, concrete formwork has always been a vital tool for the construction of the project. It is also very helpful for the construction quality and overall arrangement of the concrete. The importance of concrete forms is undoubtedly, but the choice of high-quality formwork is very important for better building quality. Do you know what should we pay attention to during the selection process of concrete formwork?

2019-08-29 -

The Importance of Formwork in Construction Projects

No matter what type of construction project you start, you need to prepare high-quality formwork for it. There are many reasons why concrete formwork is helpful for your project. Today, we are here to list some of the reasons why formwork is important in construction projects!

2019-08-29 -

Advantages of Plastic Building Formwork

In traditional architecture, China building is dominated by wood structures, while the west building is dominated by brick and stone structures. After entering modern society, with the advancement of science and technology, reinforced concrete has gradually become the mainstream of modern architecture. In the process of concrete pouring, it has to resort to building formwork.

2019-08-29 -

How to Store Different Kinds of Formwork?

When you want to create a construction project, you want to 100% ensure that everything works as expected. But many times, you need to think about all the things that are included in that project, and you have to adapt them in a way you can, so you can reach the best results. That’s why you may want to opt for a much better way to store your formwork. Storing concrete forms can be quite the challenge for a lot of people, yet when it comes to plastic formwork, the experience is not so hard to deal with.

2019-08-29 -

Features of Plastic Formwork and Plywood Formwork

The most common concrete formwork on construction site used to be plywood formwork, although some big projects such as bridges and dams may use steel formwork, as steel formwork is more strong than plywood, in business and residential building market, plywood occupy most of the shares.

2019-08-29 -

Why Steel Is the Most Recycled Material?

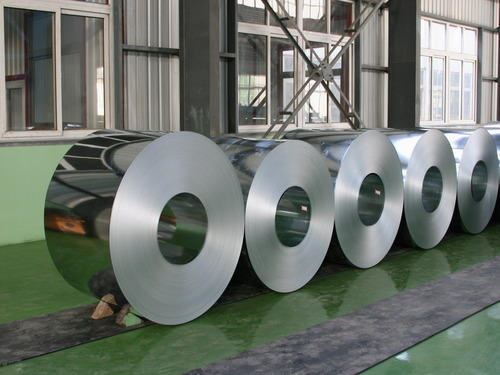

Steel is the most recycled materials on the planet. More of it is recycled every year than all other materials in the world combined, with more than 12 million tonnes being recycled in 2016 alone. Steel is one of the most reused materials in the world. Here we take a look at why steel is recycled.

2019-08-27 -

How the Steel is Recycled?

The steel recycling process involves a few keys steps. This will vary between different locations, however, the general process will remain the same (it is very similar to the steel making process).

2019-08-27 -

When Do Buildings Need Outdoor Fire Escapes?

Fire escapes stairs are relics of a bygone era. You will notice that you never see a new building with a fire escape stair. I'm not aware of any municipality that still allows for their construction of new buildings. Fire escape stairs were constructed to provide, as the name implies, egress in the case of a fire or other non-specific disaster. Because buildings are prohibitively expensive and have historical value, we allow older buildings with fire escapes to be "grandfathered in" despite the fact that the fire escapes do not meet current design codes. Similar exemptions are allowed for elevators, staircase dimensions, the presence of or lack of wheelchair-accessible ramps, etc.

2019-08-27 -

What is the Procedure for Working with Sheet Metal?

Sheet metal is one of the most widely used materials in manufacturing and is formed by rolling metal into thin ‘sheets’ that are easy to process. Metal sheets are useful in metalworking as they can be cut, bent and shaped into many different forms that are essential for construction.

2019-08-23 -

What is Sheet Metal Fabrication?

Sheet metal is used in almost every manufacturing industry, from electronics and appliances all the way through to medical equipment. Needless to say, without it, things would be pretty difficult.

2019-08-23 -

The Aesthetic Benefits of Structural Steel

Steel is beautiful stuff to build with. Watching a building come together, whether it’s a residential dwelling or a commercial structure, is thrilling, and while there are a plethora of elements that go into the process, structural steel plays a most important role in shaping aesthetics. There are many benefits of building a steel-framed house or commercial structure, but we want to take a moment to consider the aesthetic benefits of structural steel.

2019-08-22

Live Chat

Live Chat