ADTO News

-

Pipes Fittings & Flanges: Brief Introduction of Weld Neck Flanges

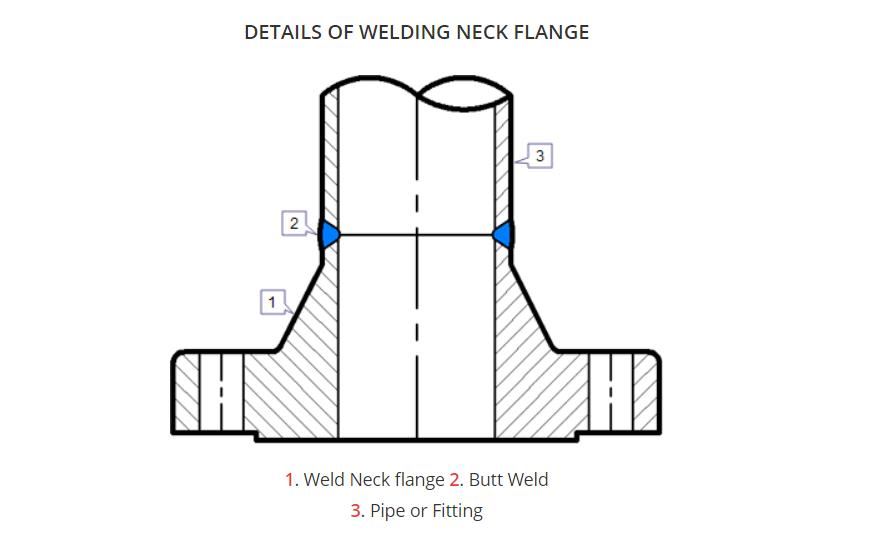

Weld Neck Flanges are distinguished from other flange types by their long tapered hub and gentle transition of thickness in the region of the butt weld that joins them to pipe or fitting. A weld-neck flange is attached to a pipe or a fitting with a single full penetration, “V” bevel weld. The long tapered hub provides an important reinforcement of the flange proper from the standpoint of strength and resistance to dishing.

2019-09-29 -

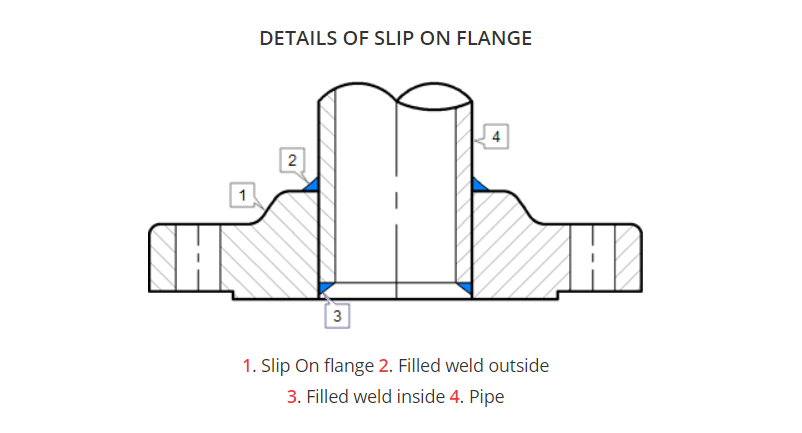

Why Slip On Flange Connection is Not Strong As Weld Neck and Socket Connection?

Slip-on flanges are preferred to weld-neck flanges by many users because of their initial low cost and ease of installation. Their calculated strength under internal pressure is about two-thirds of that of weld-neck flanges. They are typically used in low-pressure, low-hazard services such as fire water, cooling water, and other services.

2019-09-29 -

Steel Pipe: Materials for Pipe

Engineering companies have materials engineers to determine materials to be used in piping systems. Most pipe is of carbon steel (depending on service) is manufactured to different ASTM standards. The carbon-steel pipe is strong, ductile, weldable, machinable, reasonably, durable and is nearly always cheaper than pipe made from other materials. If a carbon-steel pipe can meet the requirements of pressure, temperature, corrosion resistance, and hygiene, it is a natural choice.

2019-09-27 -

Advantages and Disadvantages of Socket Weld fittings

Advantages and Disadvantages of Socket Weld fittings

2019-09-27 -

Common Types of Flange: Stub End, Threaded Flange, and Blind Flange

A Stub End always will be used with a Lap Joint flange, as a backing flange. These flange connections are applied, in low-pressure and non-critical applications, and is a cheap method of flanging. In a stainless steel pipe system, for example, a carbon steel flange can be applied, because they have not come in contact with the product in the pipe.

2019-09-27 -

Pipe & Fitting: Definition and Details of Socket Weld Fittings

A Socket Weld Flange is a pipe attachment detail in which a pipe is inserted into a recessed area of a Valve, fitting or flange. In contrast to buttweld fittings, Socket Weld fittings are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal diameter is NPS 2 or smaller.

2019-09-26 -

Steel Pipe: Definition and Details of Pipe

The pipe is a hollow tube with round cross-section for the conveyance of products. The products include fluids, gas, pellets, powders and more. The word pipe is used as distinguished from tube to apply to tubular products of dimensions commonly used for pipeline and piping systems. On this website, pipes conforming to the dimensional requirements of ASME B36.10 Welded and Seamless Wrought Steel Pipe and ASME B36.19 Stainless Steel Pipe will be discussed.

2019-09-26 -

Common Types Of Flange: Slip-on Flange

Slip-On Flange can be made from a number of different materials depending on the piping material and the requirements of the application. Selection depends on factors such as environmental corrosion, operating temperature, flow pressure, and economy. Some of the most common materials include carbon steel, alloy steel, stainless steel, cast iron, copper, and PVC.

2019-09-26 -

Common Types of Flange: Welding Neck Flange

As already described before, the most used flange types ASME B16.5 are Welding Neck, Slip-On, Socket Weld, Lap Joint, Threaded and Blind flange. Today, we ADTO GROUP want to introduce the Welding Neck Flange, completed with a detailed image.

2019-09-25 -

Common Types of Flange: Socket Weld Flange

Socket Weld flanges were initially developed for use on small-size high-pressure piping. Their static strength is equal to Slip-On flanges, but their fatigue strength 50% greater than double-welded Slip On flanges.

2019-09-25 -

Common Types of Flange: Lap Joint Flange

Lap Joint Flanges have all the same common dimensions as any other flange named on this page however it does not have a raised face, they used in conjunction with a "Lap Joint Stub End".

2019-09-25 -

Insulating Concrete Forms: More Reliable and Energy Saving Building Construction Formwork

Most of the people are now more concerned about the benefits of building environmentally friendly, energy-efficient homes and business structures. They expect more than before, for example, today, rising energy costs play a significant role in this new awareness, but still, consumers need comfort, safe housing that will keep on providing reserve funds far into the future.

2019-09-23 -

Insulated Concrete Forms: Best Choice for New Construction

In the field of the global residential, commercial, institutional and industrial building, insulated concrete forms have come up with a revolution. An insulated concrete form is a building system made from concrete, now in the limelight due to its cost-effectiveness, comfort, durability, energy efficiency and safety ratings as compared to the other traditional methods of construction.

2019-09-23 -

What Requirements Should Be Fulfilled By a Good Concrete Formwork?

If you want to do a new building project, you must need a good concrete formwork that will give you the quality and value you need. With that in mind, there are lots of options that you can focus on, some of which are more challenging when compared to others. Because of that, we listed all those requirements that should be fulfilled by a qualified concrete formwork.

2019-09-20 -

Why Should You Use the ADTO Concrete Formwork System?

If you want to create a robust and durable building, you need to opt for the very best concrete formwork on the market. Since concrete starts its life as a semi-solid, you need some stellar concrete forms that will help you model it in any way you want. That’s what makes concrete so great, the fact that you can easily work with it and manipulate it in just about any way you want. That delivers some incredible results and the value can be second to none in the end.

2019-09-19

Live Chat

Live Chat