ADTO News

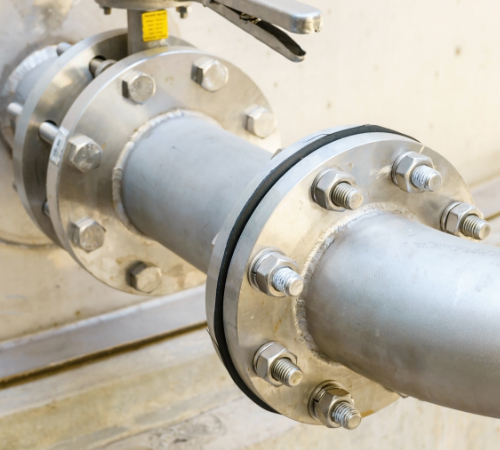

What are the Standards and Specifications For Steel Pipe Flanges in Malaysia?

In Malaysia, steel pipe flanges typically adhere to international and regional standards and specifications to ensure quality and compatibility within various industries.

Some of the commonly followed standards include:

1. ASME (American Society of Mechanical Engineers) Standards:

ASME B16.5 which covers pipe flanges and flanged fittings in nominal pipe sizes from NPS 1/2 to NPS 24. It specifies dimensions, materials, tolerances, pressure-temperature ratings, and marking requirements for various types of flanges such as weld neck, slip-on, blind, socket weld, and threaded flanges.

ASME B16.47 which is applicable for large diameter steel flanges in sizes NPS 26 and above.

2. API (American Petroleum Institute) Standards:

API 6A is relevant for flanges used in the oil and gas industry, particularly in wellhead and Christmas tree applications. It defines requirements for pressure-containing equipment including flanges in extreme operating conditions.

3. Malaysian Industrial Standards (MS):

While Malaysia may have its own localized versions or adaptations of international standards to suit specific regional requirements and regulations. For example, in certain infrastructure projects or local manufacturing processes, specific MS codes might be referenced in addition to or in conjunction with international standards to ensure compliance with local safety and quality norms.

In terms of materials, common specifications include using carbon steel with specific grades like ASTM A105 for general-purpose flanges, and for more corrosive environments, stainless steels such as 304 and 316 might be specified according to the application requirements and industry standards. Additionally, the surface finish, welding procedures, and quality control tests such as radiographic testing for welds are also defined by these standards to ensure the integrity and reliability of the steel pipe flanges.

Live Chat

Live Chat