ADTO News

-

Difference Between Stainless Steel and Galvanized Steel

Plain carbon steel will still rust quite easily in most environments if not protected. Due to this, there are many ways steel has been modified to prevent corrosion. Two popular solutions are using stainless steel or galvanized steel. While both sheets of steel resist rusting and corrosion, there are important differences between them that should be understood.

2021-08-27 -

Do You Know What is Stainless Steel?

Stainless steel is able to resist corrosion because of the additional alloying elements in its chemical makeup. While plain carbon steel consists of mostly iron and carbon, stainless steel has substantial additions of chromium to help it resist corrosion. The chromium, and sometimes other alloying elements, are added to the stainless steel during the initial melting process, prior to it being formed into any particular shape.

2021-08-24 -

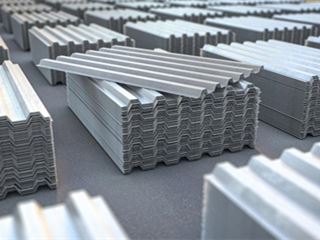

What is Galvanized Steel?

Galvanized steel is a type of steel that has been coated in a layer of zinc that helps prevent the underlying steel from rusting. This layer is usually quite thin, often measured in thousandths of inches or microns. To create galvanized steel, the zinc layer is typically added well after melting, refining, and shaping the steel plate or sheet. Sometimes it is even done after manufacturing processes have been performed on it such as bending or welding.

2021-08-24 -

Do You Know the Different Galvanizing Methods?

As the name implies, Hot-Dipped Galvanizing involves dipping the base steel into a molten pool of zinc. First, the base steel must be cleaned either mechanically, chemically, or both to assure a quality bond can be made between the base steel and the zinc coating. Once cleaned, the base steel is then fluxed to rid it of any residual oxides that might remain after the cleaning process. The base steel then dipped into a liquid bath of heated zinc and a metallurgical bond is formed.

2021-08-19 -

The Difference Between Steel Tube And Hollow Bar

Steel tubes and hollow bars are used in a wide variety of structural applications. They offer a cost advantage to solid steel bar stock, while weighing less than a solid bar of the same material and size, yet still providing much strength. While tube and hollow bar can be similar in shape, we will look at the difference between steel tube and hollow bar.

2021-08-17 -

What Do You Know About Galvalume?

It is important for many projects to protect steel from oxidation. As we are known, applying a zinc coating (known as galvanizing) to steel is one common method to prevent corrosion. There is another method to prevent corrosion known as Galvalume. But Do you know what is Galvalume?

2021-08-12 -

What is the difference between standard shade net and reflective shade net?

Standard shade net is an affordable, extremely durable means of protecting plants and crops from direct sunlight. A shade net is placed on the exterior roof of a greenhouse, cold frame, or high tunnel where it blocks a percentage of light from penetrating the building, hence keeping plants more comfortable. This type of shade material is appropriate for general gardening, farming, and greenhouse applications and is widely used in the commercial farming and gardening industry.

2021-08-09 -

What is Shade Netting and What is Its Usage?

Shade net is a lightweight knitted polyethylene knitted fabric that provides plants and people with protection from the sun. Shade cloth fabric is available in densities ranging from 30% to 95% to suit the unique needs of different types of plants, flowers, and crops. It can be used with greenhouses, hoop structures, and in-field applications.

2021-07-30 -

Threaded Rebar Coupler Splice

The taper-threaded mechanical coupler is designed for applications that require the joining of reinforcing bars. The compact design of each coupler ensures suitability for use in confined situations where space is restricted or where the loss of cover must be minimized. Taper-threaded couplers are normally supplied fitted to the end of the threaded bar, requiring only the engagement and tightening of the adjoining bar on site.

2021-07-29 -

Rebar Coupling Sleeve Mechanical Splice

Metal-filled Coupling Sleeve is placed end to end in the metal sleeve with a molten metal filler in the tap hole. The filler material flows between the bars and the sleeve, solidifying in the deformations of the rebar and the internal ribs of the sleeve, forming a mechanical interlock.

2021-07-28 -

Four Different Types of Rebar Mechanical Splices

#1 Coupler for Thread-Deformed Bar This type of deformed bar comes with special bars with thread-like rolled deformations. These are assembled with lock nuts and threaded couplers, then the nuts are tightened to the specified torque.

2021-07-27 -

Do You Know The Advantages of Rebar Mechanical Splices?

Rebar mechanical splices are used to establish a mechanical connection between two pieces of rebars in concrete construction for joining reinforcing bars. The mechanical splicing system aligns and secures the joined rebar ends in an in-line connection suitable to meet appropriate splice requirements.

2021-07-20 -

The Major Application Of Scaffolding

Have you ever noticed that scaffolding is common used in a construction site? Yes, scaffolding plays an important role in construction sites. In this post, I’ll list three major applications of scaffolding. Let’s begin with the definition of scaffolding. As we know, scaffolding is a temporary structure erected outside a building. The scaffolding system is manufactured from galvanized steel. And it contains many parts: planks, couplers, standards. etc.

2021-07-15 -

What Does Scaffolding Safety Inspections Involve?

Regular inspection and maintenance is the most important aspect of scaffolding safety. Scaffolding safety inspections are carried out during the erection of the scaffolding system. There are many factors that have an impact on the stability of the scaffolding systems: worksite conditions, weather conditions, incidents, and other hazards.

2021-07-12 -

What Are the Applications and Advantages of Aluminum Scaffolding?

Scaffolding is a temporary structure that is used to support construction workers and construction materials. Scaffolds are often used as aluminum scaffold towers and building surfaces to construct or repair works. Whilst the preferred fabrication of scaffold over the years has been steel. But now, many scaffolds are manufactured with Aluminium or galvanized steel. The question that most will consider is why would one utilize Aluminium scaffold over steel, and what are its advantages?

2021-07-08

Live Chat

Live Chat