ADTO News

-

The Production Process of Safety Net

Construction safety nets are labor-intensive industrial products, and the production process requires several processes to complete.

2022-01-25 -

Processing And Inspection of Straight Threaded Steel Bar Connecting Coupler

The material of the straight threaded steel bar connecting coupler: the straight threaded rebar connecting coupler is made of hot-rolled alloy structural round steel. The size of the straight-threaded steel bar connection coupler should match the tooth shape and number of the tapered threads at the end of the steel bar and should meet the requirements that the bearing capacity is higher than that of the steel base material.

2022-01-24 -

Hot-dip Galvanized Steel Pipe vs Cold-dip Galvanized Steel Pipe

Hot-dip galvanized steel pipe: The hot-dip galvanized steel pipe is first pickled on the steel parts. In order to remove the iron oxide on the surface of the steel parts, after the pickling, it is passed through ammonium chloride or zinc chloride aqueous solution of ammonium chloride and zinc chloride The mixed aqueous solution tank is cleaned and then sent to the hot-dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion, and long service life.

2022-01-20 -

Do You Know What Is Frame Scaffolding?

Frame scaffolding is one of the most common types of scaffolding seen on construction sites worldwide. Typically manufactured from round tubing, the frame scaffolding is available in several different configurations, from a section that contains both a ladder and a walk-through portal to sections that are totally walk-through and sections that resemble a ladder. The typical method of constructing frame scaffolding is to use two sections of the scaffold frame connected by two crossed sections of support poles arranged in a square configuration. Workers typically assemble the scaffolding by climbing the sections as they carry the next frame and pole components with them. They then assemble the new section atop of the previous section that was built.

2022-01-10 -

Types of Packaging Machine

The packaging industry is a large industry composed of many different segments. Each segment uses specific machines that assist in the packaging processes across many different businesses. We set out to identify the most common packaging machines that serve the widest variety of businesses around the world.

2021-12-31 -

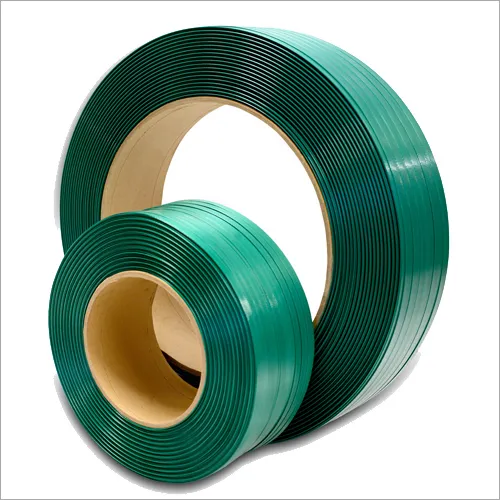

What is PET Strapping?

Polyester is the strongest plastic strap. It is often used for heavy loads that require a high tension during handling, transport, and storage. PET straps offer high tension, are able to retain this tension for a long period of time, and have an excellent stretch recovery. Because of the stretch recovery, they are excellently resistant to shocks and impacts. PET strap is light, UV resistant, recyclable, and easy to handle. These properties remain, even at high temperatures. The main disadvantage is that it is less elastic than the PP strap.

2021-12-31 -

Types of Strapping Material

The most commonly used strapping straps are Polypropylene (PP band), Polyester (PET) band, and steel strap. Each strap with its unique properties, application areas, advantages, and disadvantages. Read more about our different types of strapping material below. For more information, you can contact us directly.

2021-12-30 -

Comparison Between PET Strapping & PP Strapping

The most commonly used types of straps are Polypropylene (PP) straps, Polyester (PET) straps, and steel straps. Each type has its own unique properties, application areas, and advantages or disadvantages.

2021-12-28 -

What are Polypropylene Strip PP Strapping Tapes?

Strapping tapes are used to fix or tie finished industrial products, individual cardboards, or goods on pallets. PP strapping tapes are made of polypropylene. Polyester PET strapping tapes are characterized by high strength. Polyester (PES) strapping tapes are a modern and environmentally friendly substitute for steel straps.

2021-12-27 -

Advantages and Disadvantages of Cold Rolled Seamless Steel Pipes

Cold-rolled seamless steel pipes are cold-drawn or cold rolled precision seamless steel pipes, with high accuracy of the dimension and good finish of the surface. They are often used for machinery and hydraulic equipment.

2021-12-22 -

Advantages and Disadvantages of Hot-rolled Seamless Steel Pipe

Hot rolled is relative to the cold-rolled, cold rolling is below the recrystallization temperature of the rolling, and hot-rolled is carried out above the recrystallization temperature of the rolling.

2021-12-21 -

What Is a Seamless Steel Pipe?

A seamless steel pipe is a circular pipe without any welded seams. The seamless steel pipe has a hollow section. It is made of carbon steel, alloy steel, stainless steel ingot, or solid tube blank. There are several processes used to handle the seamless steel pipe: hot rolling, cold rolling, or cold drawing. Seamless steel pipes are considered superior to welded pipes as they are built using monolithic steel billets, with intrinsic mechanical strength, without seam welds.

2021-12-16 -

What is A Construction Safety Net?

A safety net is a net to protect people from injury after falling from heights by limiting the distance they fall and deflecting to dissipate the impact energy. The term also refers to devices for arresting falling or flying objects for the safety of people beyond or below the net. Safety nets are used in construction, building maintenance, entertainment, or other industries.

2021-12-13 -

Advantage Of Plastic Formwork

Formwork is a complete system of wooden boards, bolts, etc. Formwork is used to shape reinforced concrete or similar material while erecting. It is also called shuttering. Formworks are made of wood or metal such as steel or aluminum, but now a revolutionary material: plastic has taken over them. It comes at an affordable cost and environmentally friendly benefits. There are various types of formworks. Apart from other forms, Plastic formwork is a very complete form. Planning and material requirements are simplified concreted. This formwork is continuously adjustable and has many advantages that can be widely used in the construction field. Below we will make a small list of plastic formwork advantages.

2021-12-07 -

Common Uses for Acrow Props

Generally, Acrow props are used for scaffolding or building support to aid in the completion of the following tasks or projects: Wall removal or interior wall renovation Adding a window, doorway, or archway to a wall Installing reinforced beams and concrete sections Bracing formwork for stairs, columns, and walls Acrow props come in five main sizes, zero, one, two, three, and four, with the lower numbers indicating a stronger weight-bearing capacity.

2021-11-30

Live Chat

Live Chat