ADTO News

Professional Suggestions on How to Choose Qualified Scaffolding Planks

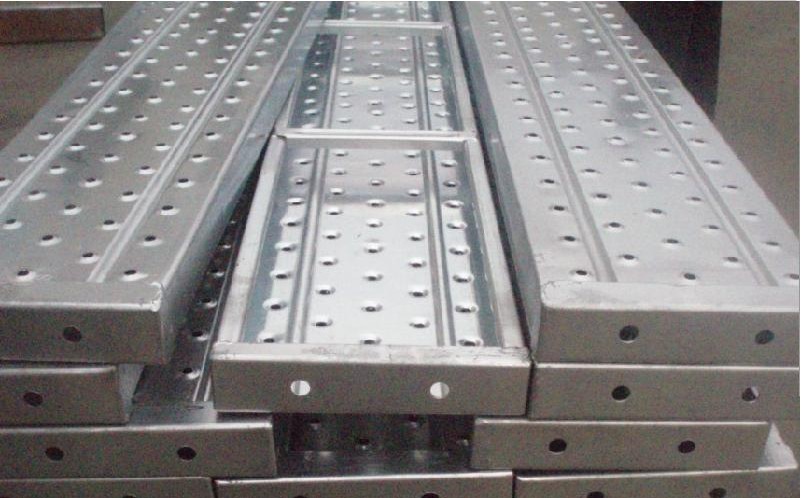

Now construction pay more attention to security, the traditional bamboo board, wood board loss is big, poor refractory corrosion and gradually fade out the market. Steel board because of its characteristics and gradually recognized by the market, and in the construction industry, shipbuilding industry, petroleum and petrochemical engineering was introduced. But currently on the market of steel board price is differ, what factors affect the price of steel board?

The following ADTO steel board manufacturer from their own scaffolding planks to illustrate the impact of steel prices in the process of production of several factors:

1, steel scaffolding planks as its name implies is refers to use the steel plate produced by ringlock scaffolding plank, steel market prices directly influences the direction of the steel scaffolding planks;

2, the thickness of the product specification. Different specifications and thickness of the product in the production of materials is also different, less material steel scaffolding planks will naturally lower price;

3, the production process. The thicker the product material, stamping the harder, making craft is complex, steel scaffolding planks higher prices is also a matter of course.

1, steel material. Small hot-dip zinc steel springboard manufacturers and large hot-dip zinc steel manufacturers of steel hardness have substantial distinction, some steel board manufacturer material cannot meet the requirements, in a few months to crack, affect the service life of steel board. But big steel material have quality assurance, and production technology.

2, steel plate thickness and surface treatment. Thickness decide steel springboard of use fixed number of year. If your period is shorter, in three to five years, then you should choose sheet thickness of 1.2 MM; If the use cycle is longer, then choose 1.5 MM thickness, the thickness of the product use fixed number of year 6-8 years.

Live Chat

Live Chat