ADTO News

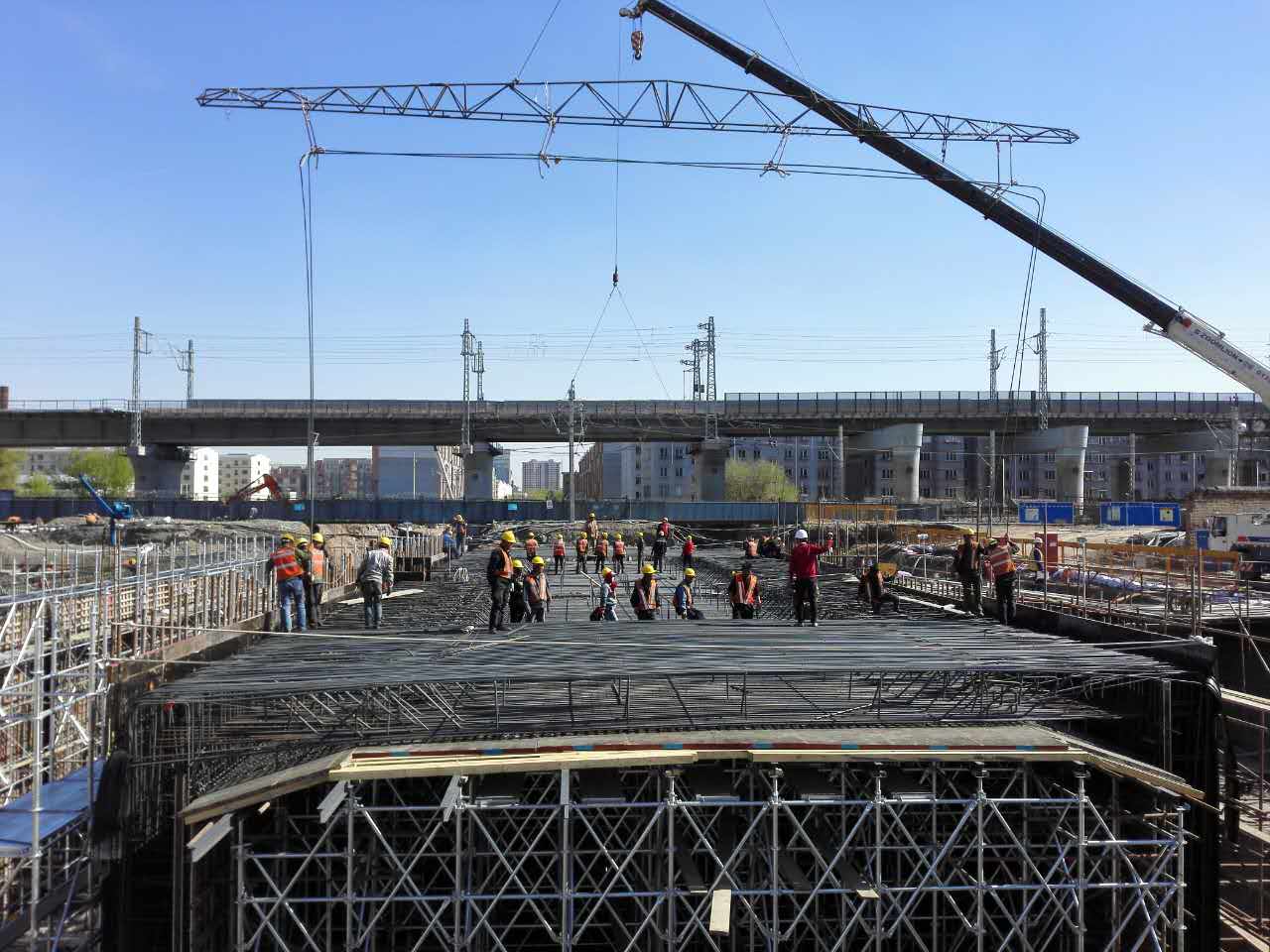

Do You Know the High Intensity of Ringlock Scaffolding Used in the Project

Ringlock scaffolding construction parts dimensional accuracy is higher, usually of CT4-6 (sand casting for CT 10 ~ 13, die-casting is CT5 ~ 7), is due to the casting technology of large building fastener products

Factors influencing the ringlock scaffolding construction parts dimensional accuracy is relatively more, tightening the pattern material (for example, building deformation of fastener products, shell in the growth process of the heat and cooling line quantity change, contraction rate of alloy fastener manufacturers, and during the course of agglutination deformation of building ringlock scaffolding fittings, etc.,

To be ordinary building fastener product size precision is high, but still need to progress the equality (acceptance, high temperature of the wax in ringlock scaffolding construction accessories size same sex to make more progress).

If construction fastener products load is too big, can make such faint show growth.

With the growth of high-speed aircraft engine, the fracture toughness of the hardened steel has completely means less than satisfied with the requirement.

But carbide segregation, must hold a repeat (axial upsetting, radial) pull to forging, with low carbon is not symmetrical, progress using performance.

To cause overheating structure bulky fastener products, can accept fastener manufacturers to forge refine grain essentials to eliminate defects, guard against fastener products of orange peel shape appearance defects during cold deformation, improve the appearance quality of fastener products.

From whether fully accepting respectively on ceramic material has two examples: one is out of steel ring growth on ceramic rotating body, called compound; And the other is a ring body are made of ceramic, known as the ceramic type.

Live Chat

Live Chat