ADTO News

Do you Know the Difference Between PPGI and PPGL Steel Sheets?

PPGI and PPGL steel sheets are two different kinds of color-coated steel sheets. PPGI and PPGL steel sheets are widely used in various industries. For example, advertising, construction, transportation, appliance industry, etc. PPGI and PPGL steel sheets are very similar. But there are still some differences between them. So, do you know what are the differences between PPGI and PPGL sheets? Let’s find out the differences.

The Difference Between Substrates

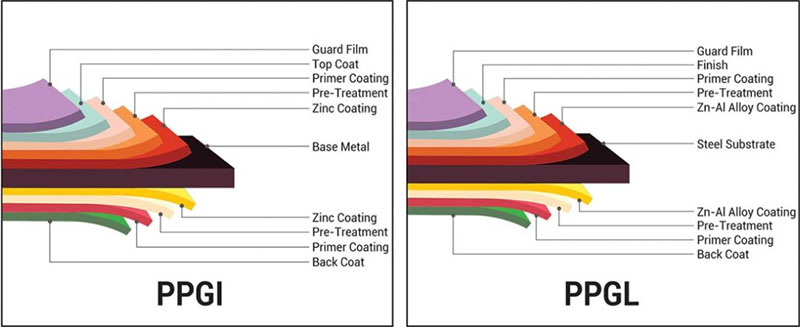

PPGI is short for pre-painted galvanized steel, while PPGL is short for pre-painted galvalume steel. As the name suggests, PPGI uses galvanized sheets (with a layer of zinc coating) as the base metal. While PPGL is with galvalume sheet as the substrate, which is coated with 55% aluminum, 43.3% zinc, and 1.6% silicon. This is the main difference between PPGI and PPGL, which will further influence their features and applications.

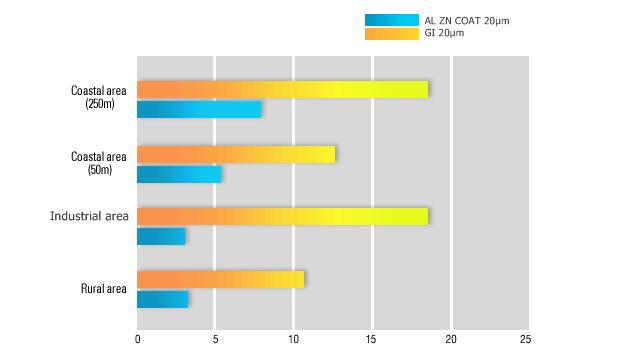

The Difference Between Service Life

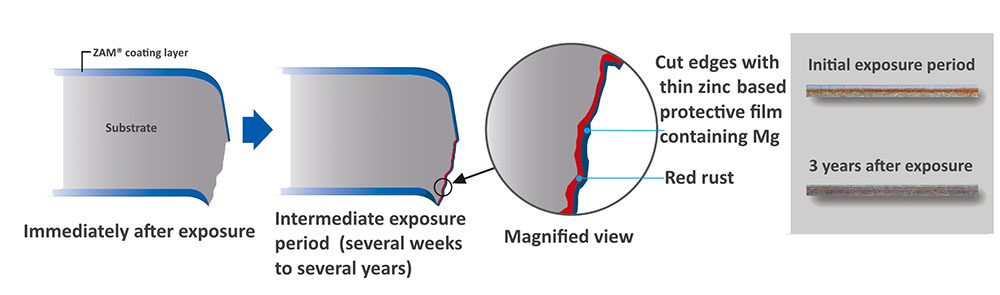

As mentioned, both zinc coating and Al-Zn coating are used to protect the metal from rusting to prolong its service life. For the GI sheet, the base metal will be damaged when the zinc coating is all corroded. Generally, a galvanized sheet may last for 10 to 15 years. While aluminum and zinc alloy forms microscopic particle areas. The Zn-rich phase will corrode preferentially, while the Al-rich phase will corrode very slowly. So Al-Zn coating is more corrosion-resistant than zinc-coated steel sheet. According to data, the service life of PPGL is 3 times longer than that of PPGI. Below are some pictures for you.

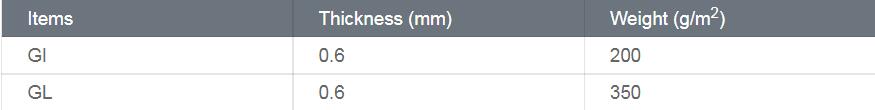

Weight Difference

With the same coating thickness, Al-Zn coating is lighter than zinc coating. It is because the specific weight of aluminum is lower than that of zinc. That is to say, with the same weight, the Al-Zn coating can cover 3% more space than the GI sheet.

Appearance Difference

The surface of the PPGL sheet is smoother than that of the PPGI sheet. It is because of the better adhesion of aluminum than zinc. For the same reason, PPGL sheets can be painted directly without pre-treatment. However, it is necessary to be pre-treated for galvanized sheets.

Features and Performance Differences

The heat resistance of the PPGL sheet is better than that of the PPGI sheet. PPGL sheet can withstand temperatures of 315 ℃. Also, PPGL sheets have better corrosion resistance than PPGI. It is because that the dense layer made of aluminum can prevent the base metal from further eroding.

Applications Differences

Both PPGI and PPGL sheets are widely used in wall paneling and roofing. By comparison, PPGL has better resistance to corrosion, which means it is more suitable for severe outdoor environments. Also, due to its good heat resistance and good surface conductivity, it is widely used in Chimney pipes, ovens, and lampshades, etc. However, the cut edges of PPGL are less protected. So you can use anti-rust paint or zinc-rich paint to the cut edges.

Geographically, PPGI is suitable for hot or cold places, such as Vietnam, UAE, Saudi Arabia, Libya, Russia, Canada, Finland, etc. While PPGL is suitable for rainy areas, such as Singapore, the Philippines, Kenya, Nigeria, Malaysia, Brazil, etc.

Price Difference

Due to the better performance and fewer qualified manufactures, the price of the PPGL sheet is 3%-11% higher than that of the PPGI sheet.

Which One Is Suitable for Me?

Except for the differences, PPGI & PPGL steel sheets are also very similar. Both of them have advantageous features, such as excellent corrosion resistance, formability, and ease to paint on. Both are widely used in construction, shipbuilding, vehicle manufacturing, furniture, the electrical industry, and so on.

So which one is more suitable for you? You can contact ADTOMall directly. ADTOMall will give you their professional advice according to your demand. No matter what you will use, PPGI or PPGL sheets, you will enjoy their durability, safety, and good appearance.

Live Chat

Live Chat