ADTO News

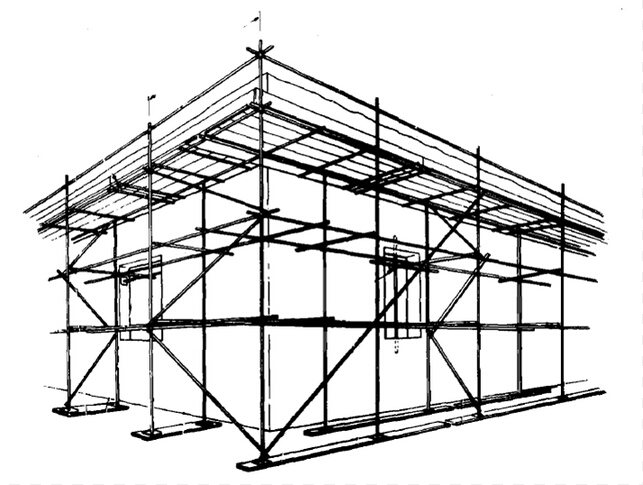

Comparison between frame scaffolding and steel tubular scaffolding.

Construction efficiency:

Frame scaffolding: It is easy to erect and remove the frame scaffolding with a construction efficiency 2-3 times higher than normal

traditional steel tubular scaffolding. And the working tense is relatively lower in such scaffolding kinds.

Steel tubular scaffolding: it is heavy and clumsy to erect and remove the traditional steel tubular scaffolding as there are more couplers. Its construction efficiency is lower with a higher working force.

Safety:

Frame scaffolding: each standing tubes in galvanized frame scaffoldings can bear a working load of more than 24kKN, which is 2.5 times of the traditional steel tubular scaffolding. The frame scaffolding has a sound and reasonable structure with higher safety ratio of 90%. Theoretically, the erection height of the scaffolding can not be over 60meters; if exceeding this height, there shall erect another triangular brackets to build a working tower.

Steel tubular scaffolding:

Each standing tubes in the traditional steel tubular scaffolding can bear a working load of more than 10KN and its safety ratio is very low. According to regulations, the assembly height of scaffolding shall be no more than 30meters; and if it is higher than 30 meters, there shall use double steel tubes at the bottom to sustain.

Live Chat

Live Chat