Product Categories

- Scaffolding

-

- Ringlock Scaffolding

- Tube and Coupler System

- Frame Scaffolding

- Kwikstage Scaffolding

- Cuplock Scaffolding

- American Style Scaffolding

- American Scaffolding

- Cuplock System Frame System Scaffold Deck Tube & Clamp Multi-function Scaffold

- Scaffolding Planks

- Scaffolding Screw Jack

- Shoring Prop

- Ladders and Staircases

- Ladder Beam

- Scaffolding Accessories

- More Scaffolding

- Steel Prop Scaffold Clamps Kwikstage System Ringlock Scaffold System Base Jack Frame Scaffold System Screw Jack

- Steel Pipe

-

- Galvanized Steel Pipe

- Pre Galvanized Steel Pipe

- Square Steel Tubing

- Rectangular Steel Tubing

- Seamless Steel Pipe

- ERW Steel Pipe

- LSAW Steel Pipe

- SSAW Steel Pipe

- Pipe Fittings & Flanges

- Stainless Steel Pipe

- Stainless Steel Welded Pipe Stainless Steel Seamless Pipe

- More Steel Tube

- Pre Galvanized Steel Tube Square Steel Pipe Rectangular Steel Pipe ERW Steel Tube LSAW Steel Tube SSAW Steel Tube

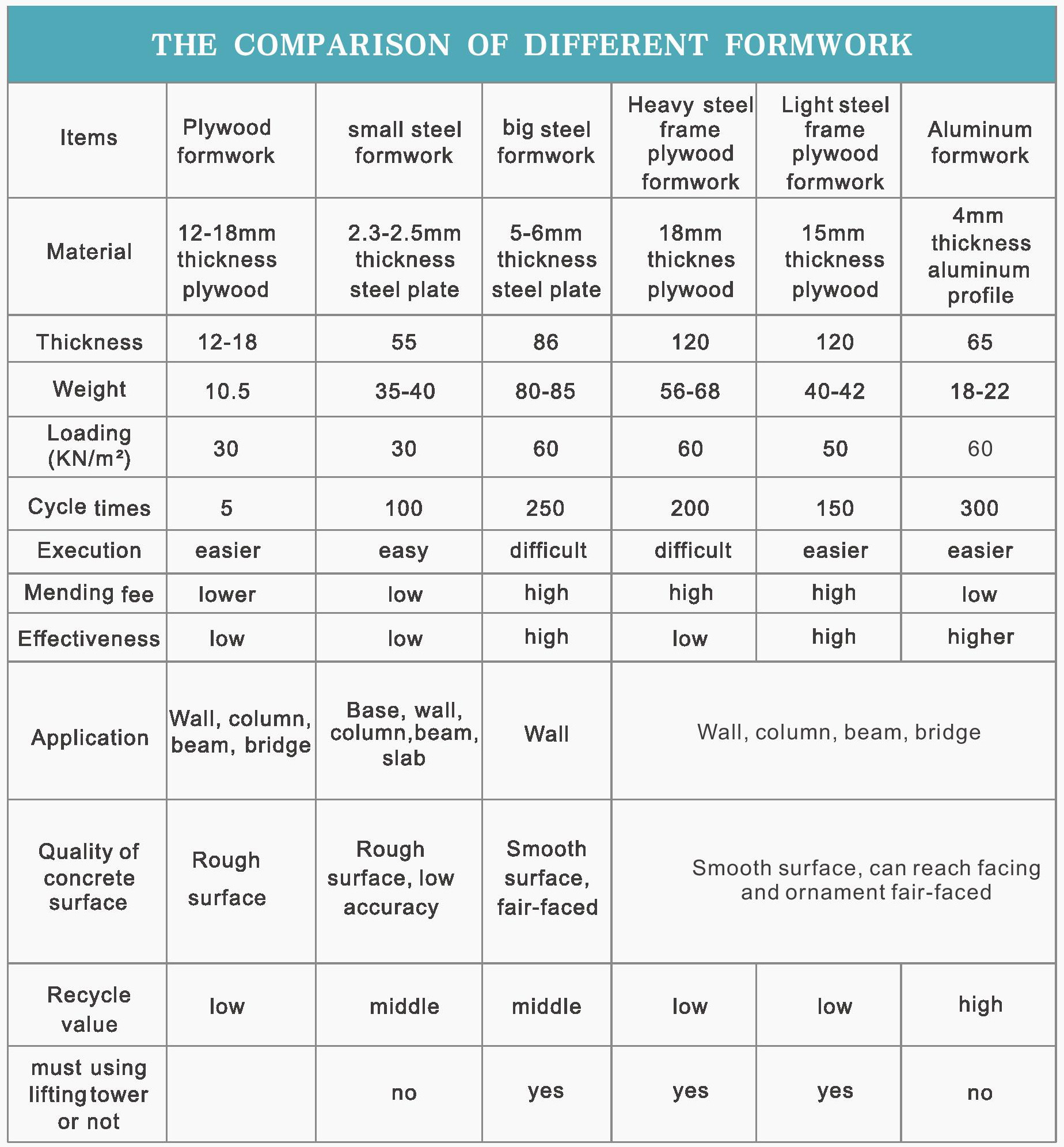

Advantages of ADTO aluminum formwork:

1. Low average cost (can be reused for more than 300 times)

2. Safe (can load 60KN/m2)

3. Light weight (22-25kg/m2)

4. Good hardness

5. High efficiency on installing & dismantling

6. Value maintain (recycling price can be 90% of the alum ingot)

7. Environmental friendly

8. Four days one floor only

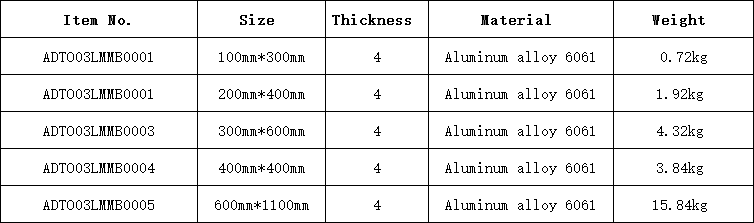

Specification:

| Place of Origin | Hubei, China (Mainland) | Brand Name | ADTO | Model Number | ADTO-F11 |

| Aluminum Series Model | 6061-T6(GB5237-2008 stand) | Surface Treatment | Hot light body | Application | Tall building/sairport/towers |

| Weight per square aluminized | 20-28kg(Standards formwork) | Features | One-time Pouring, Over 200 times to resuses | Certificate | ISO9001:2008;CE;SGS |

| Standard Formwork Length | 2.7m,2.34m,1.2m | Aluminum thickness | 4mm | Components | Beam/Pillar/Wall/Prop/Floor/Reinforcement system |

Aluminium Formwork:

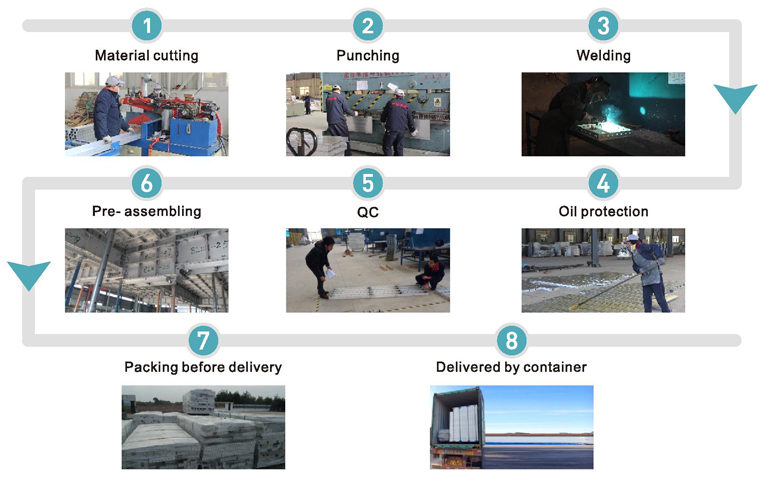

Aluminum Formwork System is an updated construction technique. It consists of small aluminum (alloy) framed panels which are very

fast and easy to erect and are so durable that can be re-used over 100 times. With the help of this Aluminum Formwork System we can

cast each slab within 10 days cycle.

We use very high strength aluminum alloy for manufacturing the aluminum forms & we take pride in our craftsmanship for manufacturing

quality, handcrafted and hand-welded forms. The panels are manufactured within our factory to very high specifications and tolerances.

Once assembled they are subjected to a trial erection in order to eliminate any dimensional or on site problems. When you choose

ADTO Aluminum Formworks, you are investing in the highest quality, most durable concrete forms in the market today. Our quality control

extends beyond the manufacturing plant, with constant reevaluation of our products, regular communication with contractors, builders

and distributors, we manufacture concrete forms designed to meet your needs.

The formwork is designed to suit your project using the most economical assortment of panel sizes. Preliminary schemes and

building layouts can be developed as an initial step to assessing commercial viability. Outline budget costing exercises are

regularly performed as a means of confirming our competitiveness.

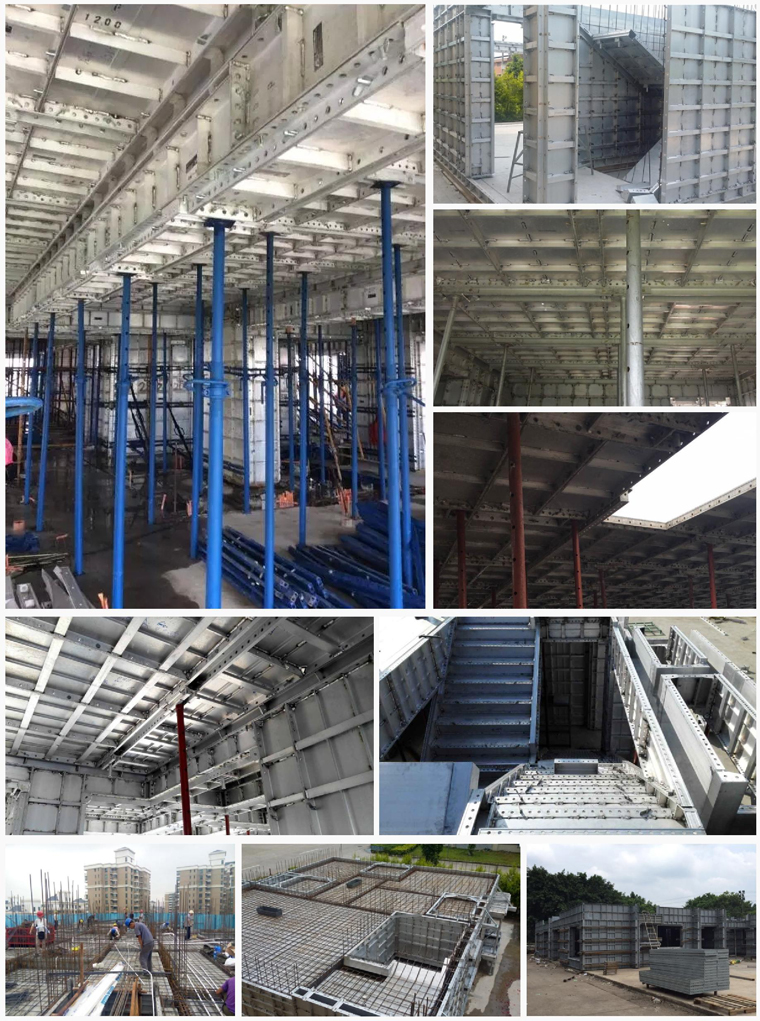

COLUMN FORMWORK SYSTEM:

The column formwork systems are normally modular in nature and allow quick assembly and erection on site while minimizing labor and

time. The formworks are made of Aluminum, can be adjusted on site to give different column sizes. They have a variety of internal surfaces

depending on the concrete finish required. Aluminum formwork systems can have integral concreting platforms with guard rails and

access equipment including ladders. This reduces the need for independent access. In some systems the props used to stabilize the

column formwork are integral. The Aluminum formworks are easy to clean and reuse over 100 times with little waste generated compared withtraditional formwork.

ADTO Aluminium Formwork can be used widely in the construction of residential units and mass housing projects. It is fast, simple, adaptable and cost – effective. It produces total quality work which requires minimum maintenance and when durability is the prime consideration. This system is most suitable for Indian condition as a tailor–made aluminum formwork for cast–in–situ fully concrete structure.

ADTO Industrial Group, Co., Limited, founded in 1998, ADTO is a leading building material supplier and manufacture in China, centering on R&D, producing and selling of building material of scaffolding, aluminum formwork, fastener and coupler, integrates business of steel, logistic and wire & cables service. The group has more than 10 subdivisions and four manufacturing bases, possessing the right to import and export with business coverages spanning over more than 50 places and areas. Over 5000 international big buyers keep ADTO as their long term business partner.

1. Experience: Founded in 1998, more than 17 years in construction materials manufacturing

2. Product Idea: Quality decided to safety, safety is the hard truth.

3. Certifications: ISO, CE, SGS, BV

4. Production base: Four factories, more than 400,000 square meters

5. OEM or Customized Service is available.

Person: Ms Zheng

Email: Info@adtomall.com

Skype: ADTOMall

Address: HuNan,China

![]() More detail, welcome to send inquiry.

More detail, welcome to send inquiry.

Live Chat

Live Chat