Product Categories

- Scaffolding

-

- Ringlock Scaffolding

- Tube and Coupler System

- Frame Scaffolding

- Kwikstage Scaffolding

- Cuplock Scaffolding

- American Style Scaffolding

- American Scaffolding

- Cuplock System Frame System Scaffold Deck Tube & Clamp Multi-function Scaffold

- Scaffolding Planks

- Scaffolding Screw Jack

- Shoring Prop

- Ladders and Staircases

- Ladder Beam

- Scaffolding Accessories

- More Scaffolding

- Steel Prop Scaffold Clamps Kwikstage System Ringlock Scaffold System Base Jack Frame Scaffold System Screw Jack

- Steel Pipe

-

- Galvanized Steel Pipe

- Pre Galvanized Steel Pipe

- Square Steel Tubing

- Rectangular Steel Tubing

- Seamless Steel Pipe

- ERW Steel Pipe

- LSAW Steel Pipe

- SSAW Steel Pipe

- Pipe Fittings & Flanges

- Stainless Steel Pipe

- Stainless Steel Welded Pipe Stainless Steel Seamless Pipe

- More Steel Tube

- Pre Galvanized Steel Tube Square Steel Pipe Rectangular Steel Pipe ERW Steel Tube LSAW Steel Tube SSAW Steel Tube

-

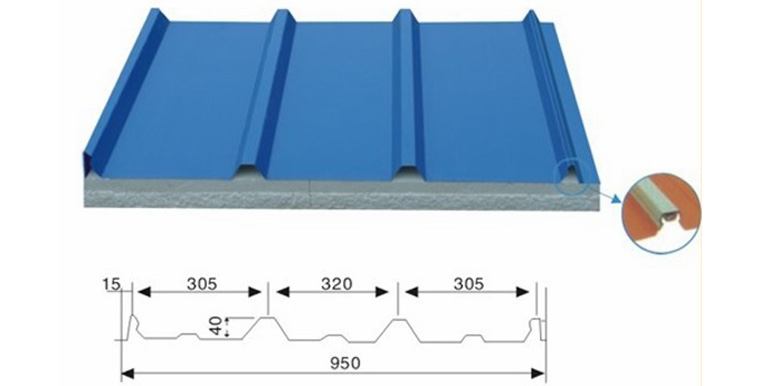

Composite plate production line (heat insulation sandwich composite plate production line), used of advanced production technology with gas, electricity, machinery into an organic whole, It’s a special equipment to produce thermal insulation galvanized steel composite panels, working speed adopts frequency conversion stepless speed regulation, can recombine to corrugated type composite panels by one time, the full assembly line consist of feeding mechanism, composite, coating, heating, edge, notching, whole side, pneumatic and automatic cutting),it is indispensable equipment to forming industrial workshop, warehouse roof panel and wall panel.

-

Composite plate production line is to put the formed pre-painted steel coil with strong adhesive on both sides of the thicker material inner core, formed a kind of new construction materials with strong strength, light weight, heat insulation, durable and good appearance. It be widely used in light steel structure building roof and wall body, the product have the character of bright color and no need decorate secondly.

|

Model No: |

ADTO-CP970 |

Application |

|

Production Capacity |

8-10m/min |

Roofing panel, wall panel |

|

Total power: |

32 kw |

|

|

Voltage |

380 V 50Hz 3phases |

|

|

Length(m) |

Min cut length:3M Max stacker length:15M |

|

|

Material coil yield strength |

235MPa |

|

|

Coil Width(mm) |

1200 as you required |

|

|

Effective width(mm) |

980/1000/1200/1250 |

|

|

Dimension(L*W*H): |

About 7500 *1300*1200mm |

|

|

Weight: |

About 17T |

|

|

Thickness of the plate |

0.3-0.8mm adjustable |

|

|

Roller material: |

45#steel Chrome Plated |

|

|

Cutting blade material |

Cr 12 high grade steel |

|

|

Diameter of Shaft |

80mm |

|

|

Roll station |

14 row Adjustable |

|

|

The material of EPS density |

≥18Kg/m3 |

|

|

straight rate |

≤1mm/m |

|

|

arch degree |

≤3mm/m |

|

|

sandwich panel length |

≥5 meters |

|

|

The flat degree of panel surface |

≤1.5mm/m |

|

|

Control system |

PLC computer control system |

|

|

Certification: |

CE/SGS/ISO |

|

The equipment model can be designed and manufactured according to customers' requirement of specification and drawing.

The equipment model can be designed and manufactured according to customers' requirement of specification and drawing.

The complete line of composite panel production line consist of:

A. Uncoiling device F. Cutting device

B. B. Roll forming system G. Stacking system

C. Preheating room H. Packing system

D. PU foam dispensing system/ I. Mineral wool cutting/feeding device

Pu glue adhesive system

E. Double belt conveyer

Un-coiler- - Laminating machine(cutting)---Roll forming machine---Worming machine--- Foaming machine---Double-belt laminating machine---Cutting part---Cooling system---stack and packing

1. Experience: Founded in 1998, more than 17 years in construction materials manufacturing

2. Product Idea: Quality decided to safety, safety is the hard truth.

3. Certifications: ISO, CE, SGS, BV

4. Production base: Four factories, more than 400,000 square meters

5. OEM or Customized Service is available.

Person: Ms Zheng

Email: Info@adtomall.com

Skype: ADTOMall

Address: HuNan,China

![]() More detail, welcome to send inquiry.

More detail, welcome to send inquiry.

Live Chat

Live Chat